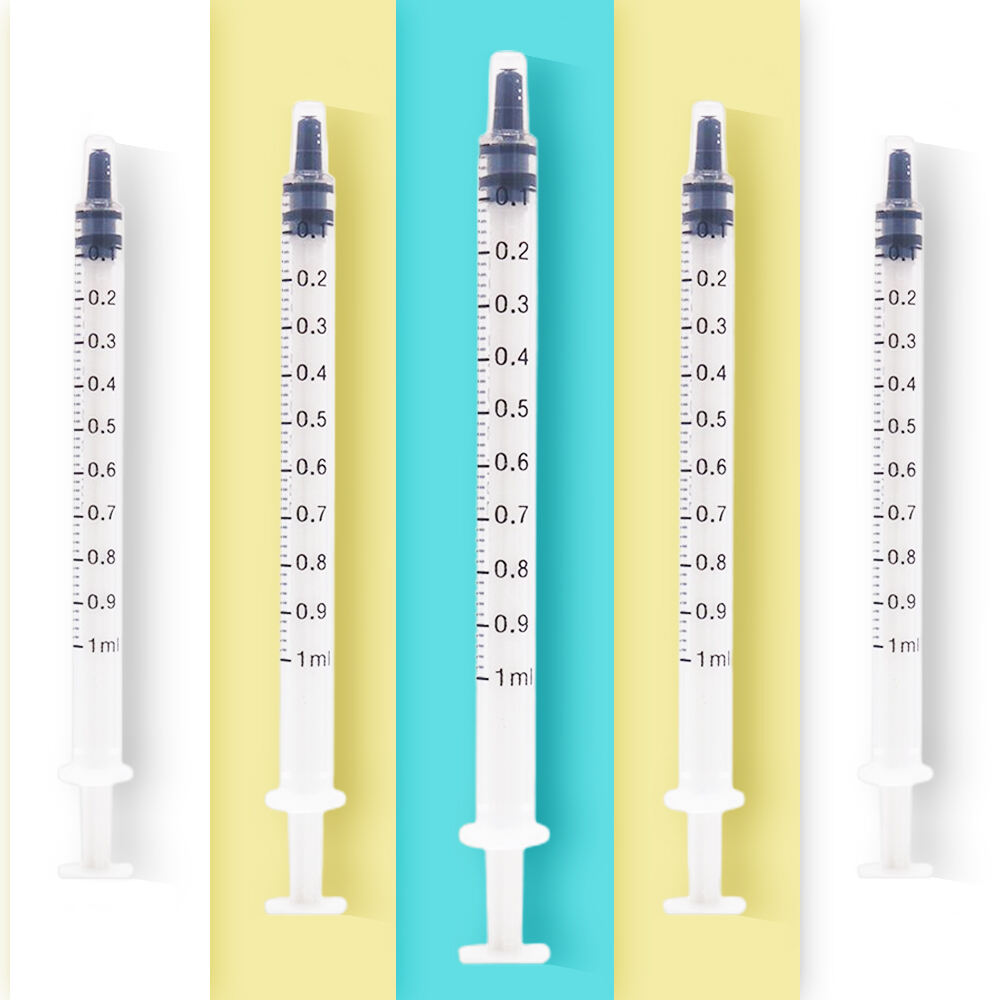

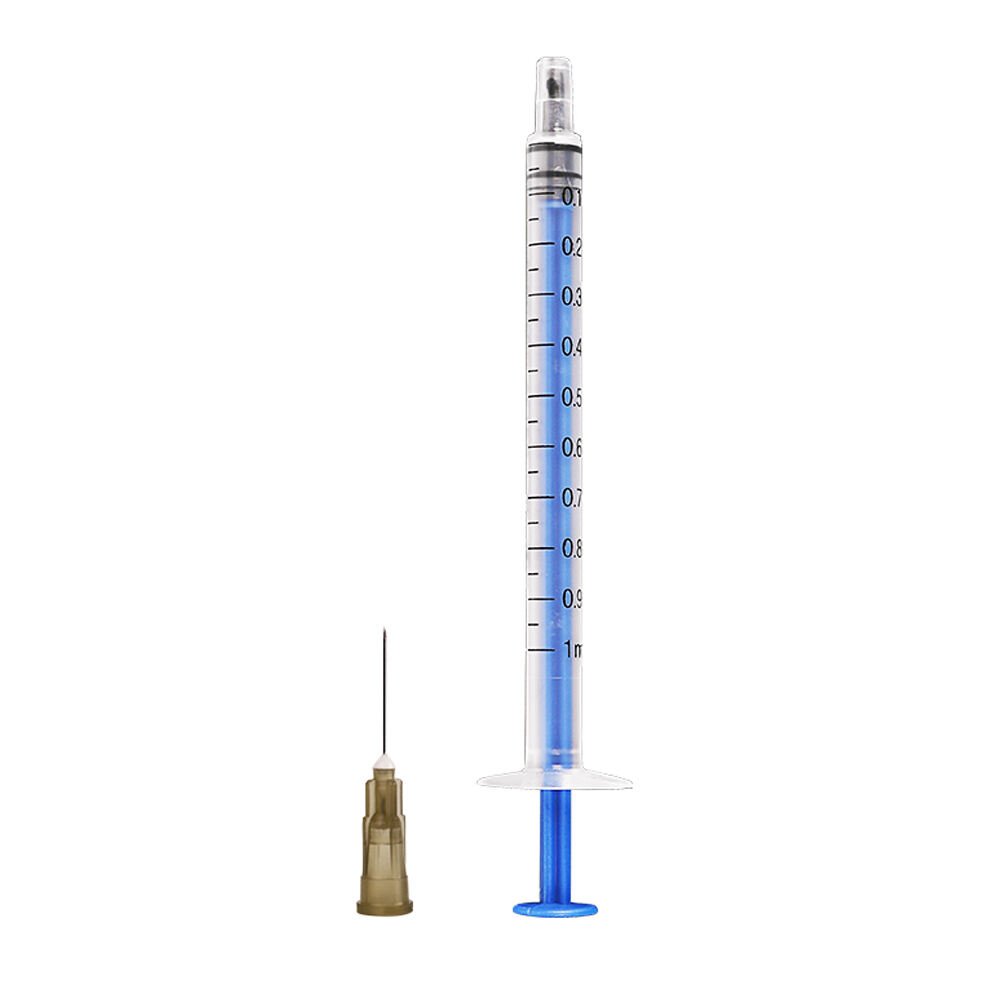

1ml syringe with cap manufacturer

A 1ml syringe with cap manufacturer specializes in producing precision medical devices essential for accurate liquid medication delivery. These manufacturers employ state-of-the-art production facilities equipped with advanced clean room technology and automated assembly lines to ensure consistent quality and sterility. The manufacturing process incorporates high-grade medical-grade materials, primarily polypropylene and latex-free components, meeting stringent international standards including ISO 13485 and FDA requirements. The production involves multiple quality control checkpoints, from raw material inspection to final product testing, ensuring each syringe meets exact specifications for capacity, needle attachment, and cap security. The manufacturer's expertise extends to various syringe designs, including luer lock and luer slip options, with specialized focus on the precise graduation markings essential for 1ml measurements. The integrated cap design provides dual functionality of sterility maintenance and needle protection, while the manufacturing process ensures smooth plunger movement for accurate dosing. These facilities typically maintain full traceability systems and implement rigorous quality management protocols to guarantee product safety and reliability.