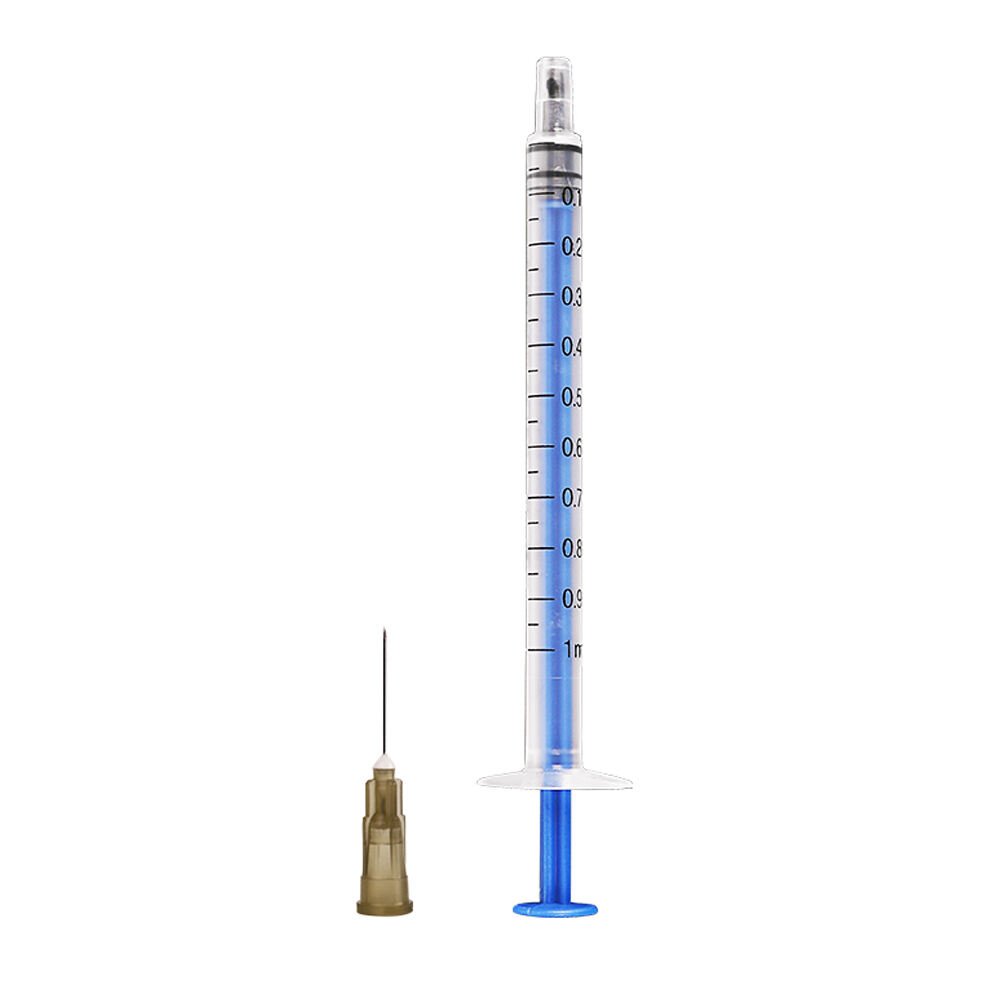

1 cc luer lock syringe manufacturer

A 1 cc luer lock syringe manufacturer specializes in producing precision medical devices that deliver accurate measurements for small volume applications. These manufacturers employ state-of-the-art production facilities that adhere to strict quality control standards and regulatory requirements. The manufacturing process incorporates advanced injection molding technology, automated assembly lines, and rigorous testing protocols to ensure consistent product quality. The syringes feature a secure luer lock mechanism that provides reliable connection to needles and other medical devices, preventing accidental disconnection during use. The clear barrel markings enable precise measurement of 1 cc volumes, while the smooth plunger action ensures controlled delivery of medications or solutions. These manufacturers typically utilize medical-grade materials that are latex-free and meet USP Class VI requirements for biocompatibility. The production facilities maintain ISO 13485 certification and comply with FDA guidelines for medical device manufacturing. Quality assurance measures include lot tracking, sterility testing, and comprehensive documentation of the manufacturing process.