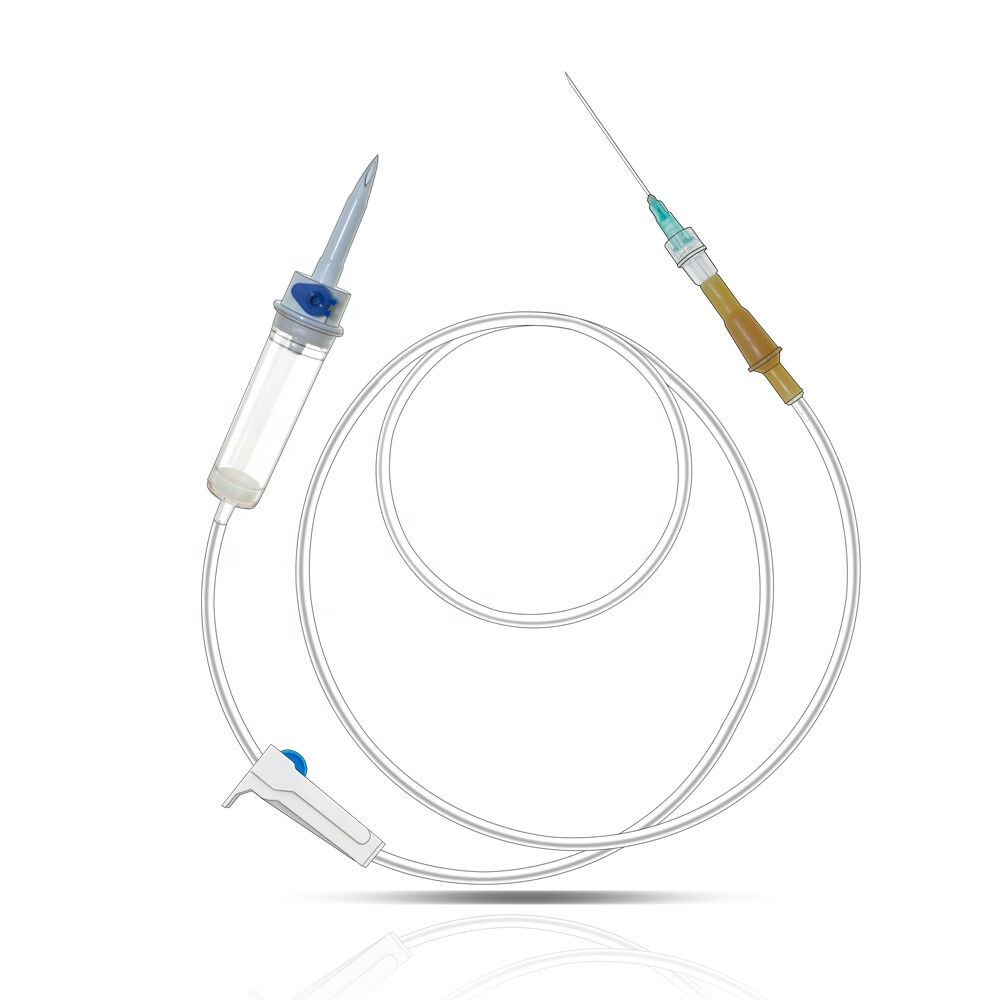

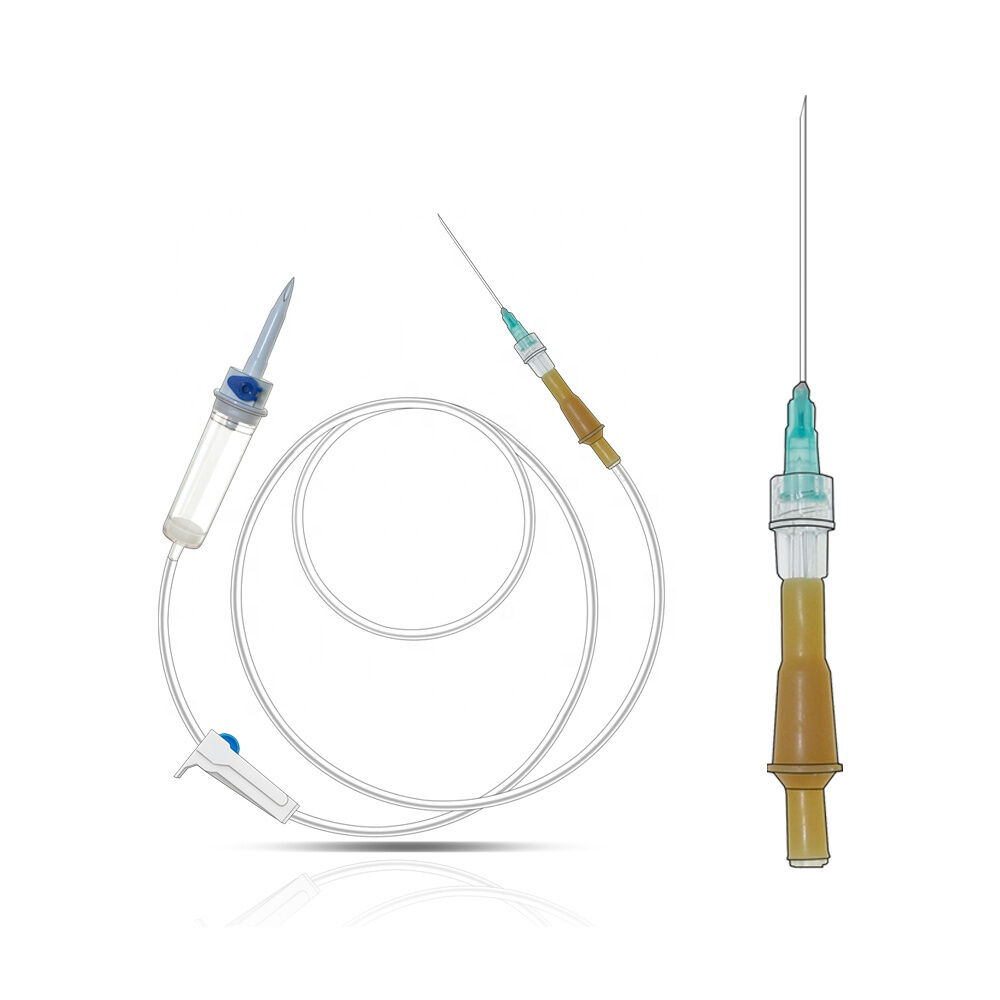

micro drip iv set manufacturer

A micro drip IV set manufacturer specializes in producing precision medical devices designed for accurate fluid delivery in healthcare settings. These manufacturers employ advanced engineering and quality control processes to create reliable infusion systems that ensure precise dosage administration. Their production facilities integrate automated assembly lines with stringent quality checks, maintaining ISO 13485 certification and FDA compliance. The manufacturing process encompasses various components including precision-molded drip chambers, roller clamps, tubing, and specialized connectors. Modern micro drip IV set manufacturers utilize innovative technologies like computer-aided design and automated testing systems to achieve flow rate accuracy within 5 percent variance. Their facilities typically feature cleanroom environments meeting ISO Class 7 standards, ensuring product sterility and consistency. These manufacturers also implement comprehensive quality management systems, covering everything from raw material selection to final product validation. They maintain rigorous documentation and traceability systems, enabling batch-specific quality control and regulatory compliance. The production capabilities often include customization options for different medical applications, from pediatric care to specialized infusion therapy requirements.