iv set with burette manufacturer

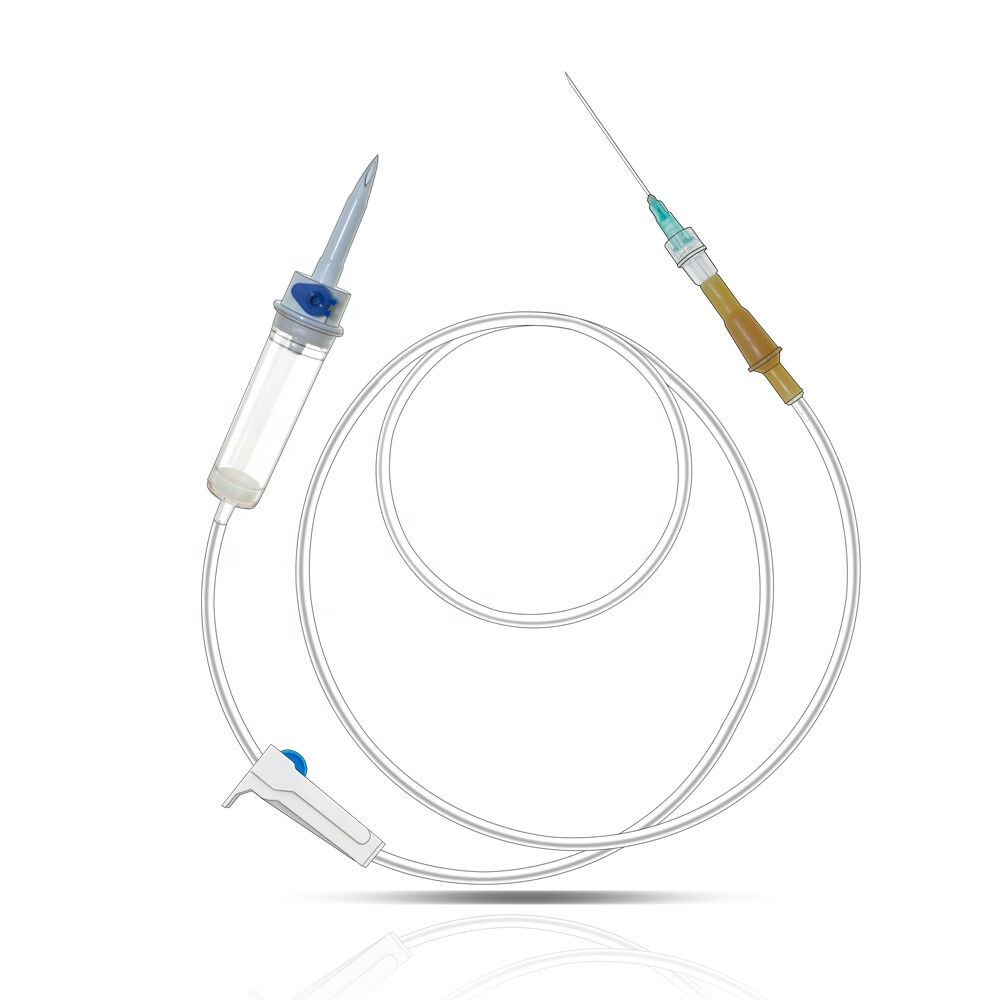

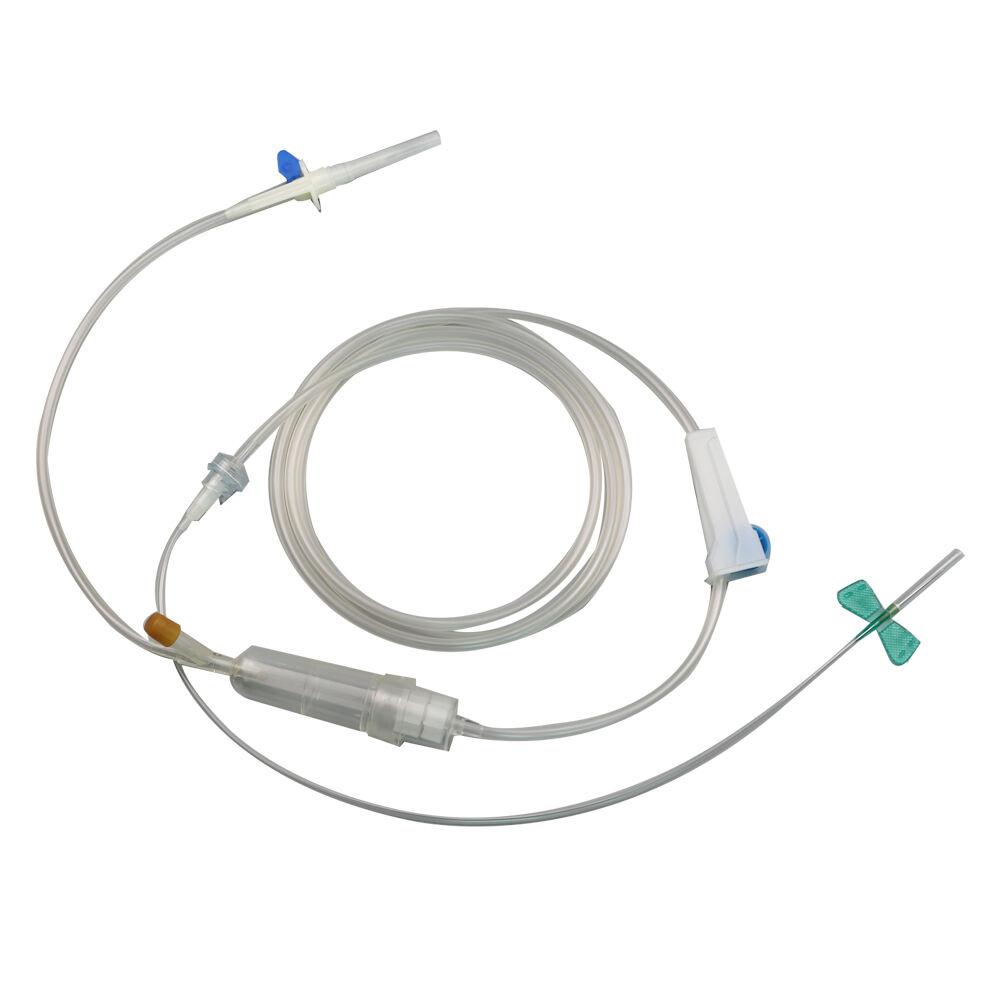

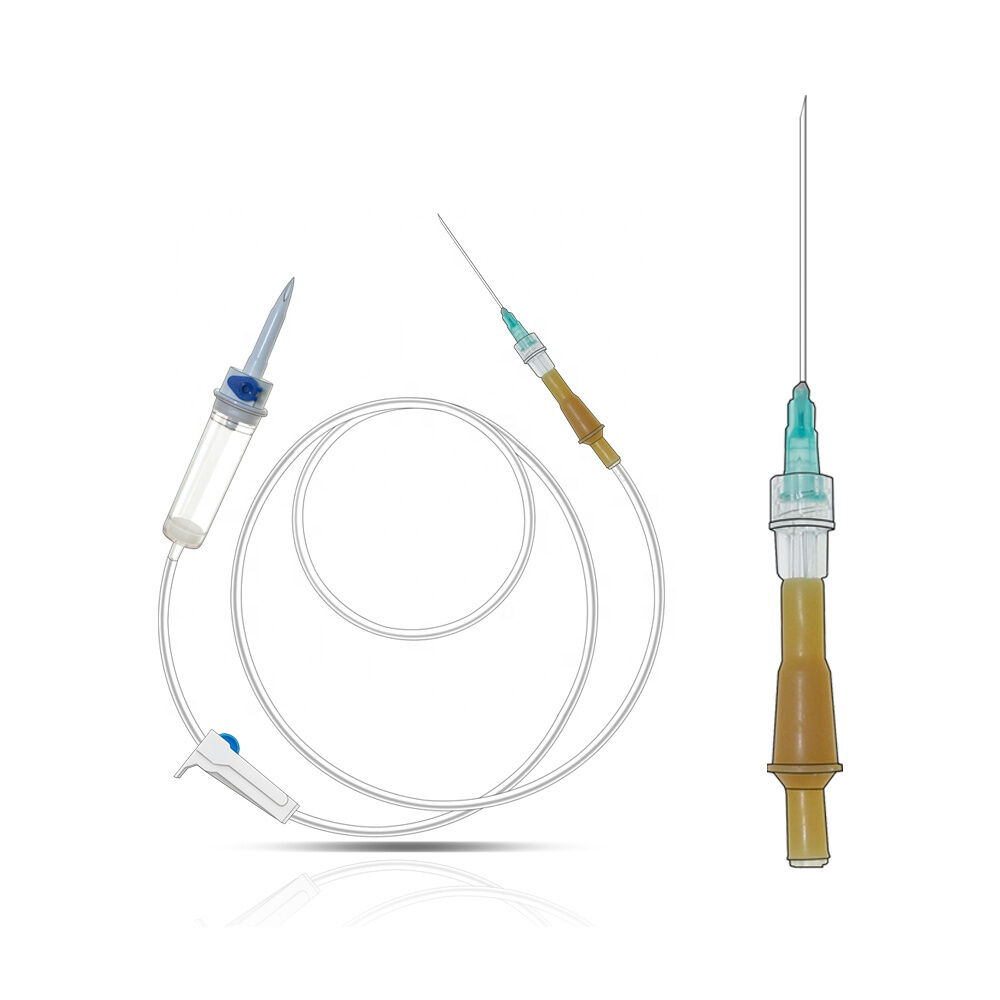

An IV set with burette manufacturer specializes in producing precision medical devices essential for controlled fluid administration in healthcare settings. These manufacturers employ advanced manufacturing processes and quality control measures to create reliable infusion systems that combine burettes with standard IV sets. The products feature calibrated chambers typically ranging from 100 to 150 mL, allowing healthcare providers to deliver precise volumes of medications and fluids. The manufacturing process incorporates medical-grade materials that meet stringent international standards for safety and biocompatibility. Modern production facilities utilize automated assembly lines equipped with quality inspection systems that ensure each component meets exact specifications. The burette chamber is designed with clear markings for accurate measurement and includes features such as air vents and filtered ports to prevent contamination. These manufacturers also implement specialized molding techniques for the drip chamber and roller clamp components, ensuring smooth flow control and consistent drop formation. Their product lines often include various configurations to accommodate different clinical needs, from pediatric care to intensive care units. Quality assurance protocols involve multiple testing phases, including leak testing, flow rate verification, and sterility validation, before products are approved for distribution to healthcare facilities worldwide.