feeding syringe for adults manufacturer

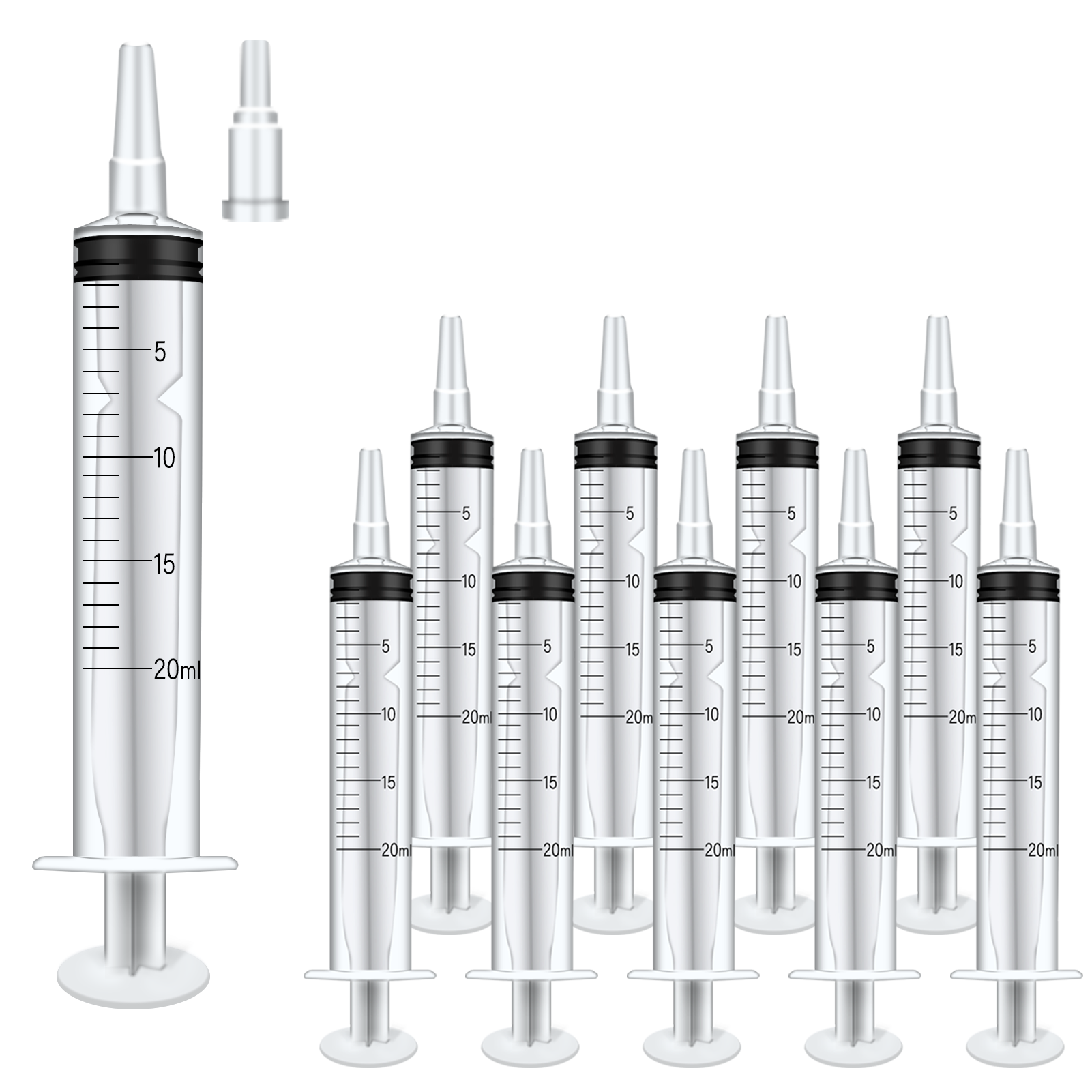

A feeding syringe for adults manufacturer specializes in producing high-quality medical devices designed for safe and accurate enteral feeding. These manufacturers employ advanced production technologies and strict quality control measures to create reliable feeding syringes that meet international medical standards. Their facilities are equipped with state-of-the-art machinery for precision manufacturing, ensuring each syringe delivers accurate dosing and smooth operation. The production process incorporates medical-grade materials that are latex-free and biocompatible, making them safe for long-term use. These manufacturers typically offer various syringe sizes, ranging from 1ml to 60ml, to accommodate different feeding requirements. The syringes feature clear barrel markings for precise measurement, ergonomic design for comfortable handling, and specialized tips compatible with various feeding tubes. Many manufacturers also implement automated quality inspection systems to verify product consistency and safety. Their research and development teams continuously work on improving design elements like plunger stability, tip security, and overall durability. Additionally, these manufacturers maintain ISO certification and comply with FDA regulations, ensuring their products meet the highest safety and quality standards for medical use.