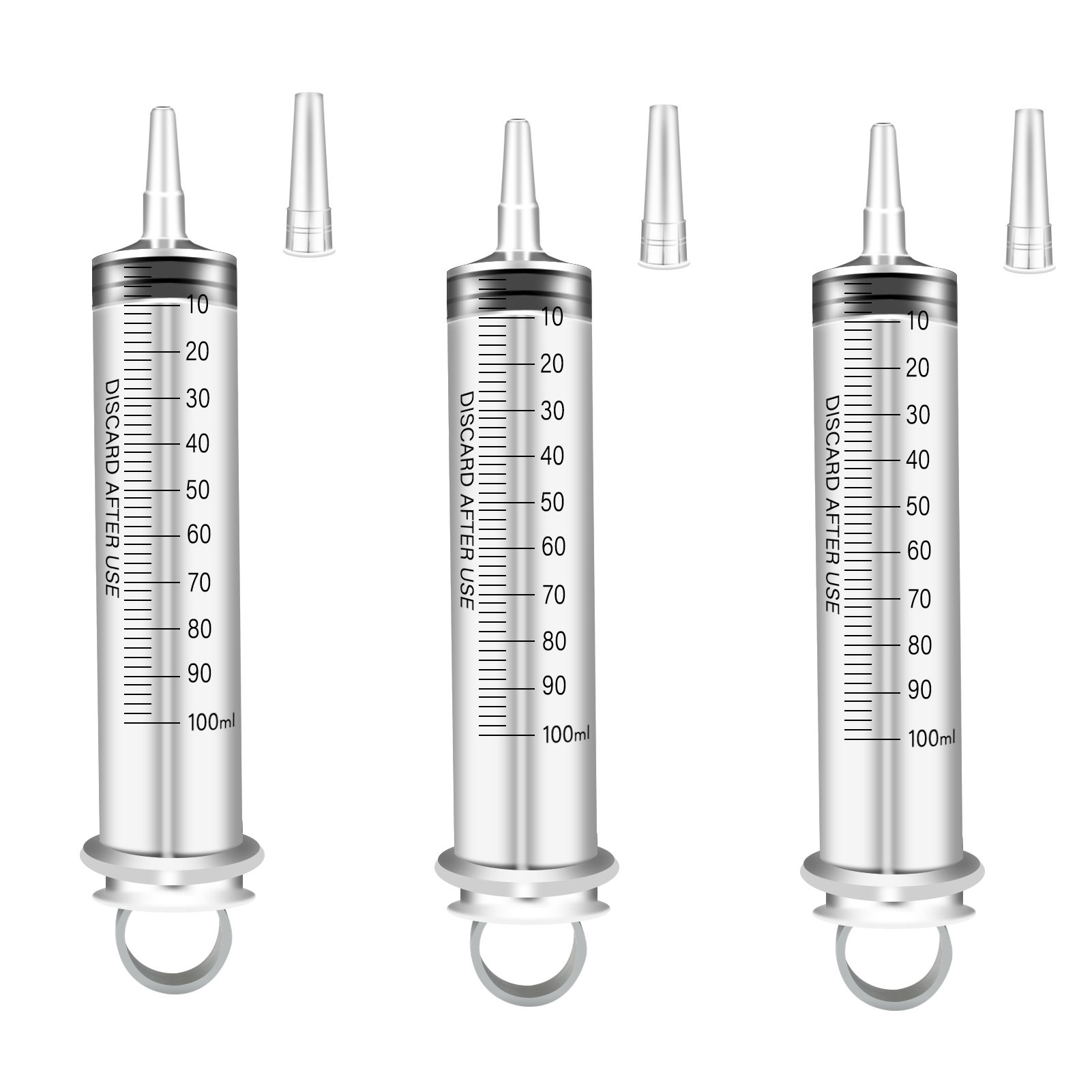

10 ml feeding syringe manufacturer

As a leading 10 ml feeding syringe manufacturer, our company specializes in producing high-precision medical devices that meet international quality standards. Our state-of-the-art manufacturing facility employs advanced injection molding technology and automated assembly lines to ensure consistent product quality. Each syringe undergoes rigorous testing for accuracy, sterility, and durability. The facility operates under strict ISO 13485 certification, implementing comprehensive quality management systems throughout the production process. Our 10 ml feeding syringes feature clear barrel markings, smooth plunger action, and compatibility with standard feeding tubes. The manufacturing process incorporates medical-grade materials that are latex-free and BPA-free, ensuring patient safety. We maintain dedicated clean rooms for production, with regular environmental monitoring and quality control checks. Our manufacturing capabilities include customizable options for different tip designs, plunger styles, and packaging configurations to meet various healthcare requirements. The facility's production capacity exceeds 10 million units annually, serving healthcare providers worldwide with reliable feeding solutions.