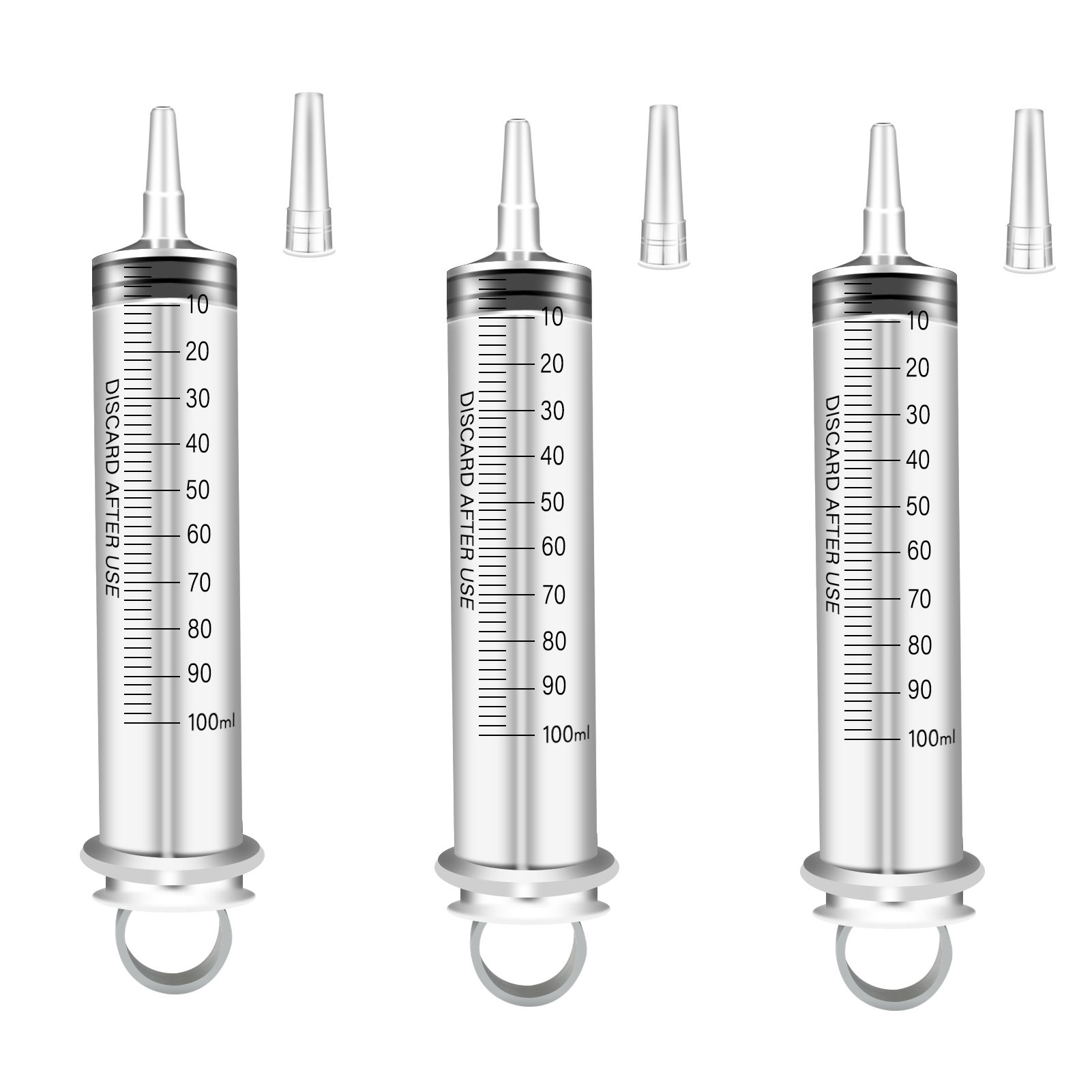

large feeding syringe manufacturer

A large feeding syringe manufacturer stands at the forefront of medical device production, specializing in the development and manufacturing of high-capacity feeding syringes designed for various medical and nutritional applications. The manufacturer employs state-of-the-art production facilities equipped with precision engineering technology to ensure consistent quality and reliability. These facilities incorporate automated production lines, clean room environments, and rigorous quality control systems that meet international standards including ISO 13485 and FDA requirements. The manufacturer's production capabilities extend from material selection and molding to sterilization and packaging, ensuring complete control over the entire manufacturing process. The company utilizes medical-grade materials that are latex-free and biocompatible, making their products suitable for both clinical and home care settings. Their production line includes feeding syringes ranging from 20ml to 100ml capacity, featuring clear barrel markings, smooth plunger action, and secure catheter connections. The manufacturer also implements advanced testing procedures, including leak detection, strength testing, and compatibility verification with various feeding tubes and nutritional formulas. This comprehensive approach to manufacturing ensures that each syringe meets the highest standards of safety and functionality for enteral feeding applications.