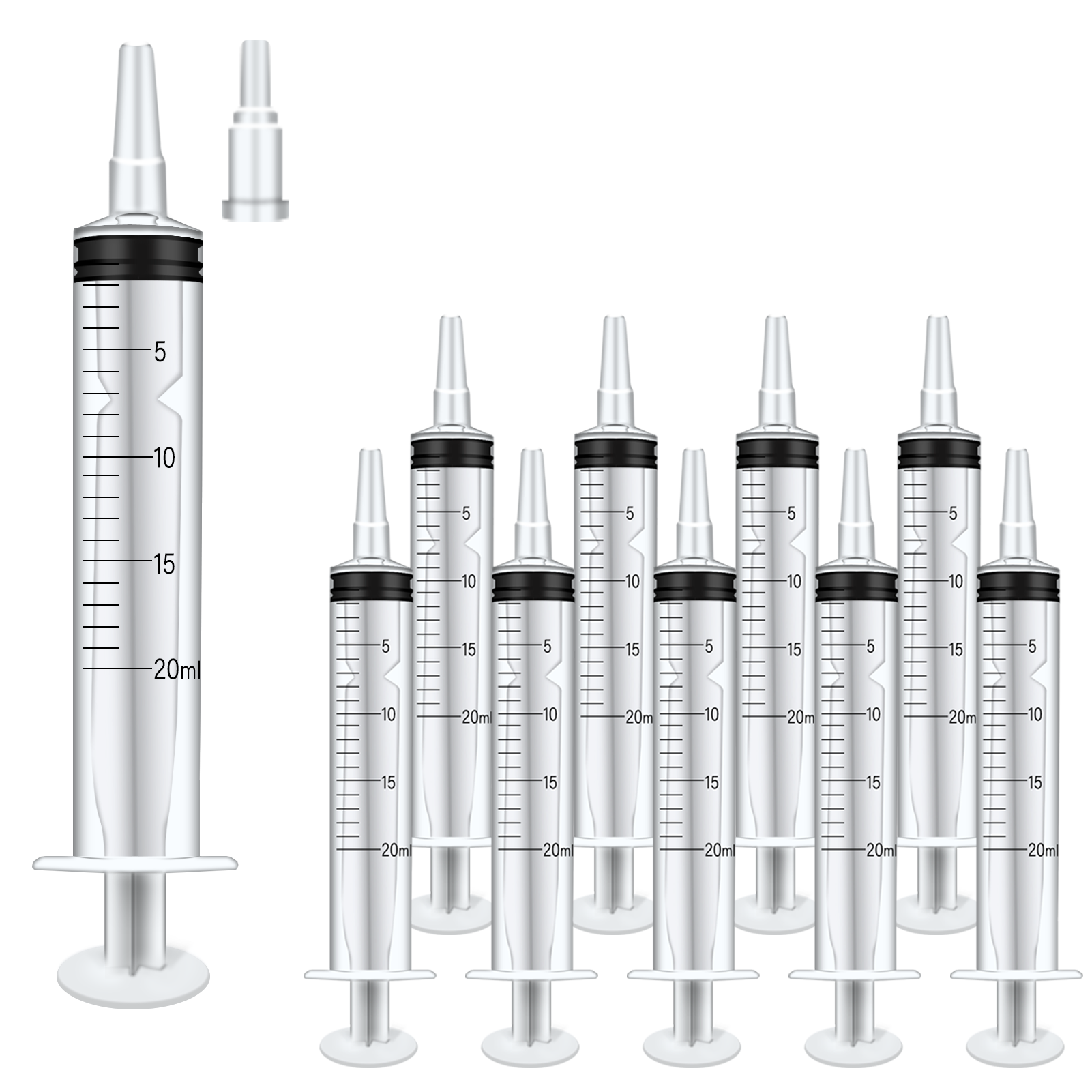

60cc feeding syringe manufacturer

A 60cc feeding syringe manufacturer specializes in producing high-quality medical devices designed for precise liquid nutrition delivery. These manufacturers employ advanced injection molding technology and medical-grade materials to create syringes that meet strict healthcare standards. The production facilities feature state-of-the-art clean rooms and automated assembly lines to ensure consistent quality and sterility. The manufacturing process incorporates rigorous quality control measures, including dimensional accuracy testing, material verification, and sterilization validation. These manufacturers typically offer customization options, such as different tip configurations and packaging solutions, to meet varying customer requirements. Their production capabilities often include high-volume manufacturing while maintaining precise tolerances and ensuring product reliability. The syringes are designed with clear barrel markings for accurate measurements, smooth plunger action for controlled delivery, and ergonomic features for comfortable handling. Many manufacturers also provide comprehensive documentation, including lot traceability and quality certificates, supporting regulatory compliance. Advanced research and development teams continuously work on improving design elements and manufacturing processes to enhance product performance and user safety.