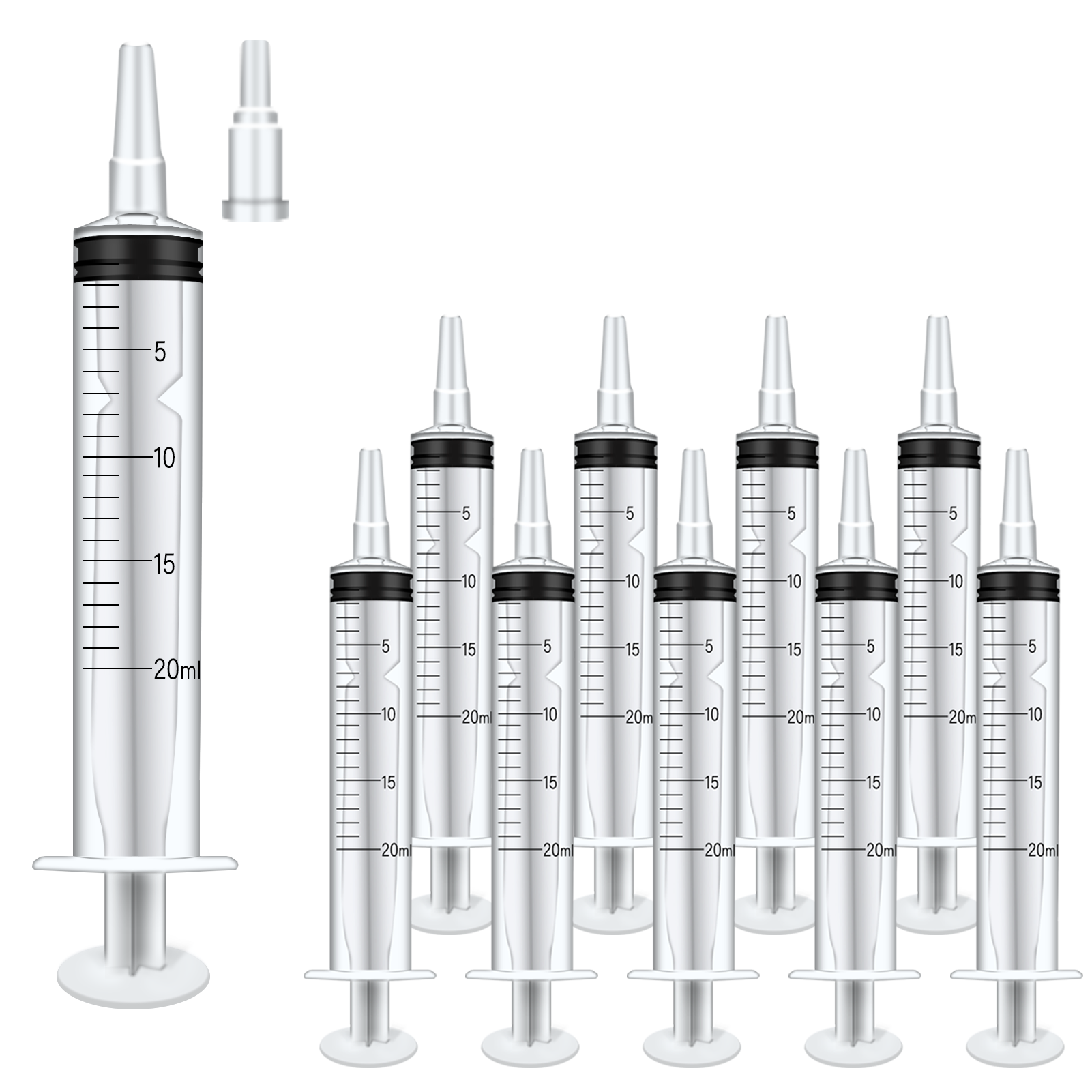

feeding syringe 50ml manufacturer

A feeding syringe 50ml manufacturer specializes in producing high-quality medical devices designed for precise liquid administration in healthcare settings. These manufacturers employ state-of-the-art production facilities equipped with advanced injection molding technology and automated assembly lines to ensure consistent quality and reliability. The production process adheres to strict medical-grade standards, including ISO 13485 certification and FDA compliance. The syringes feature clear barrel markings for accurate measurements, smooth plunger action for controlled delivery, and are manufactured using medical-grade polypropylene materials. The manufacturing facility maintains cleanroom environments to prevent contamination and implements rigorous quality control measures at every production stage. These 50ml feeding syringes are designed with universal compatibility for various feeding tubes and come with secure luer lock or catheter tip options. The manufacturer's expertise extends to specialized coating technologies that reduce friction and ensure smooth operation, while also incorporating ergonomic design elements for comfortable handling by healthcare professionals.