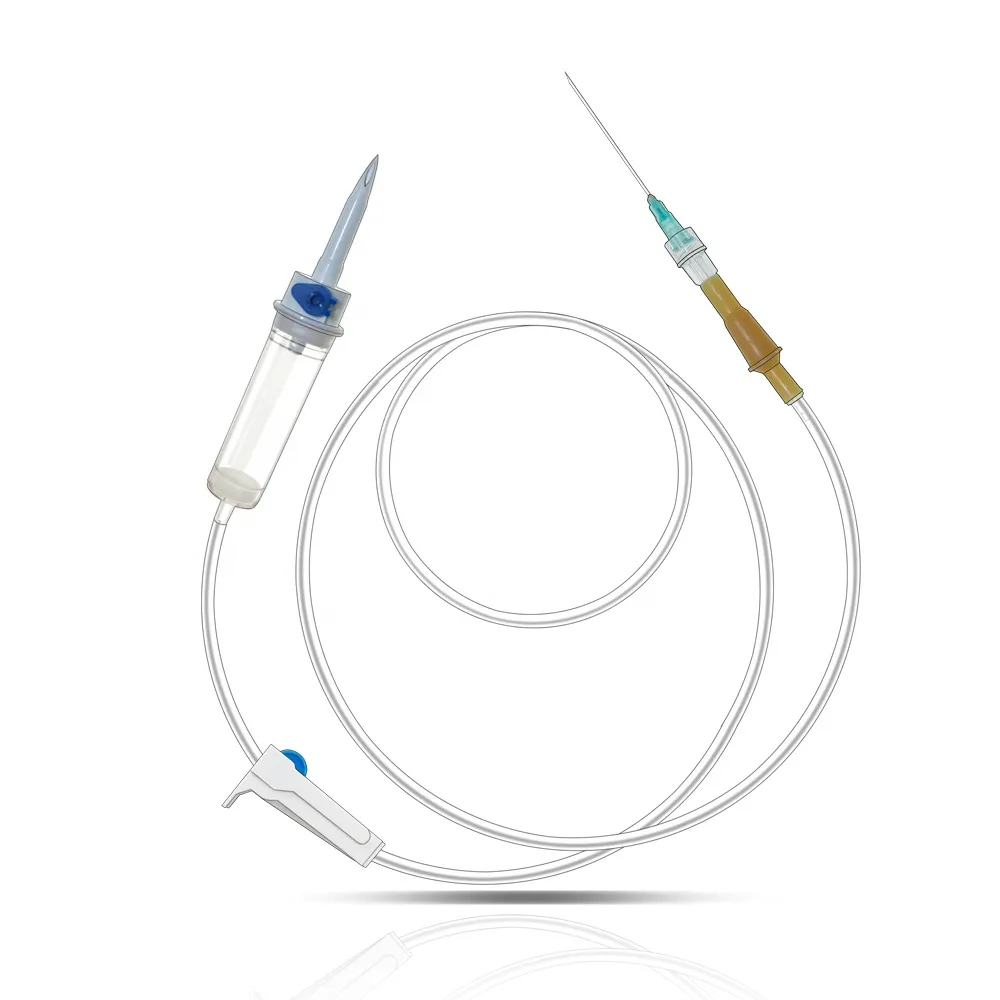

syringe with needle 5ml manufacturer

A syringe with needle 5ml manufacturer specializes in producing high-quality medical devices essential for healthcare applications. These manufacturers employ advanced production technologies and stringent quality control measures to ensure each syringe meets international medical standards. The manufacturing process involves precision engineering of both the syringe barrel and needle components, utilizing medical-grade materials that guarantee sterility and reliability. The 5ml capacity is particularly versatile, making it suitable for various medical procedures, from routine vaccinations to specialized treatments. Modern manufacturing facilities incorporate automated production lines with clean room environments, maintaining strict adherence to ISO 13485 standards and FDA regulations. The production process includes multiple quality checkpoints, from raw material testing to final product inspection, ensuring consistency in needle sharpness, barrel graduation accuracy, and smooth plunger action. These manufacturers often integrate innovative features such as safety mechanisms and ergonomic designs to enhance user experience and patient safety. The commitment to quality extends to packaging solutions that maintain product sterility and protect integrity during transportation and storage.