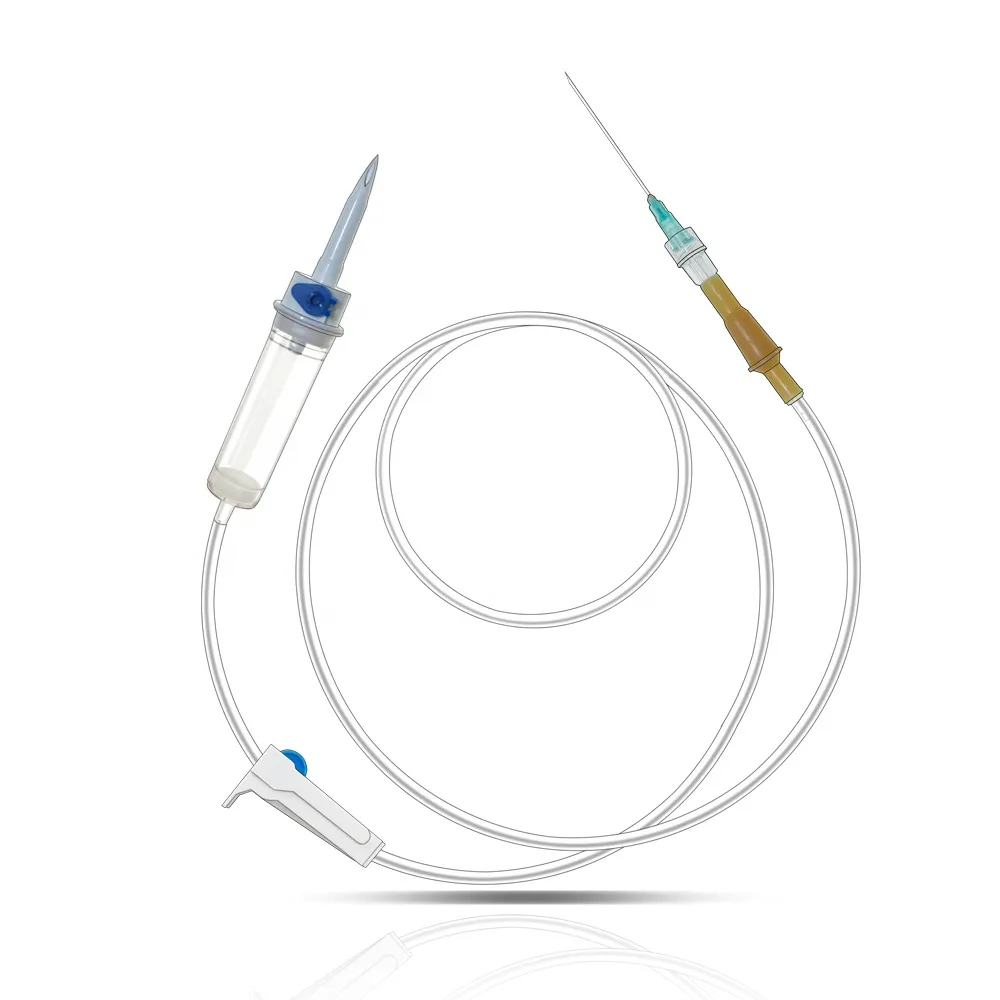

iv infusion set with flow regulator manufacturer

An IV infusion set with flow regulator manufacturer specializes in producing high-precision medical devices essential for controlled fluid delivery in healthcare settings. These manufacturers employ advanced engineering and quality control processes to create reliable infusion sets that ensure accurate medication administration. The manufacturing facilities utilize state-of-the-art technology and automated systems to produce sterile, medical-grade components that meet international safety standards. The flow regulators are designed with precise calibration mechanisms that allow healthcare providers to adjust fluid delivery rates with exceptional accuracy. These manufacturers typically incorporate features such as anti-free flow mechanisms, air-in-line detection, and precise drip chambers to enhance patient safety. The production process includes rigorous testing phases, ensuring each component meets strict medical device regulations. Manufacturers also focus on developing user-friendly designs that facilitate easy setup and operation by medical professionals. The materials used are carefully selected for biocompatibility and durability, often including medical-grade PVC tubing and precision-engineered flow control mechanisms. These manufacturers maintain ISO certification and follow Good Manufacturing Practice (GMP) guidelines, ensuring consistent quality across their product lines. Their facilities often include clean rooms for assembly and specialized testing equipment for quality assurance.