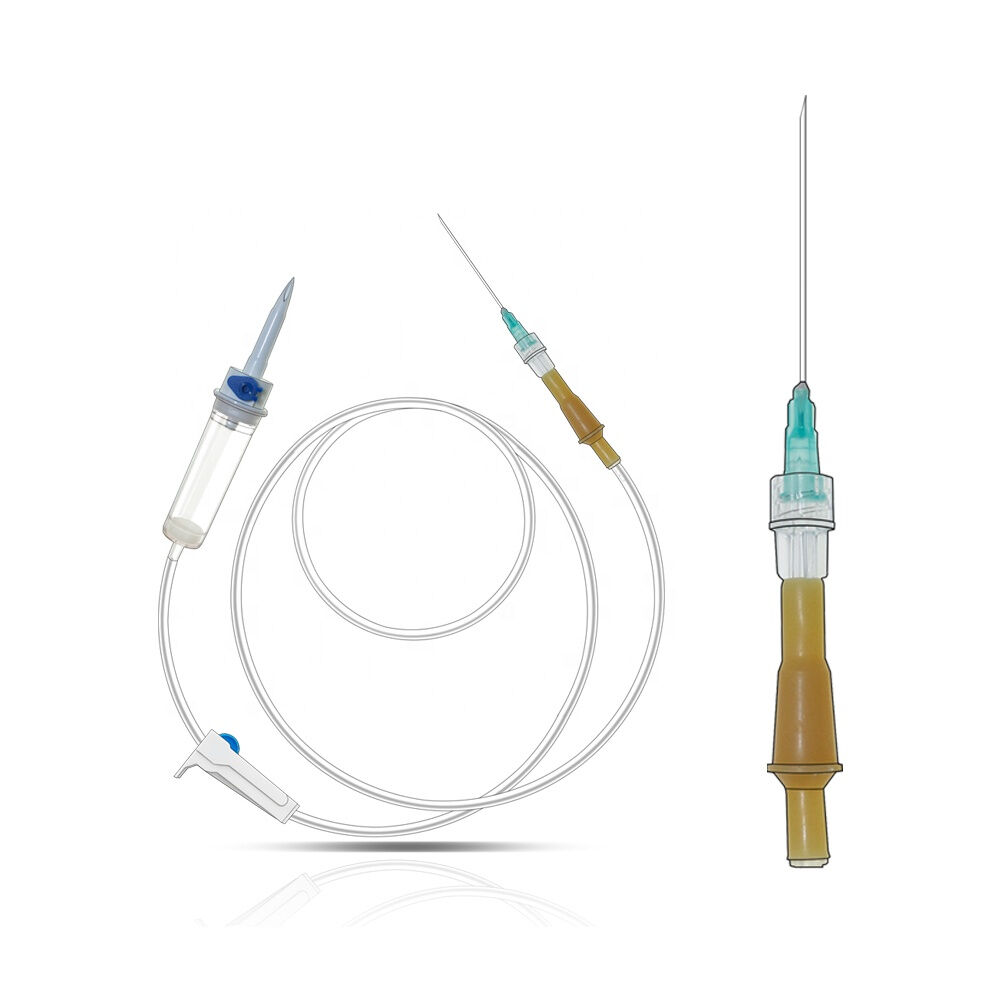

micro drip infusion set manufacturer

A micro drip infusion set manufacturer specializes in producing precision medical devices designed for controlled fluid delivery in healthcare settings. These manufacturers employ advanced manufacturing processes and stringent quality control measures to create reliable infusion sets that accurately deliver medications, nutrients, and other therapeutic solutions. The production facilities typically feature state of the art clean rooms, automated assembly lines, and sophisticated testing equipment to ensure product consistency and safety. These manufacturers incorporate innovative design elements such as precise drop forming chambers, accurate flow regulators, and specialized filters to prevent air embolism. The manufacturing process includes multiple quality checkpoints, from raw material inspection to final product testing, ensuring compliance with international medical device standards. Their production capabilities often extend to various specialized infusion sets, including those with different flow rates, filtering capabilities, and connection types to meet diverse medical requirements. The facilities maintain ISO certification and follow Good Manufacturing Practice (GMP) guidelines, implementing robust quality management systems throughout the production cycle. These manufacturers also invest in research and development to continually improve their products, focusing on enhanced safety features, user friendly designs, and cost effective production methods.