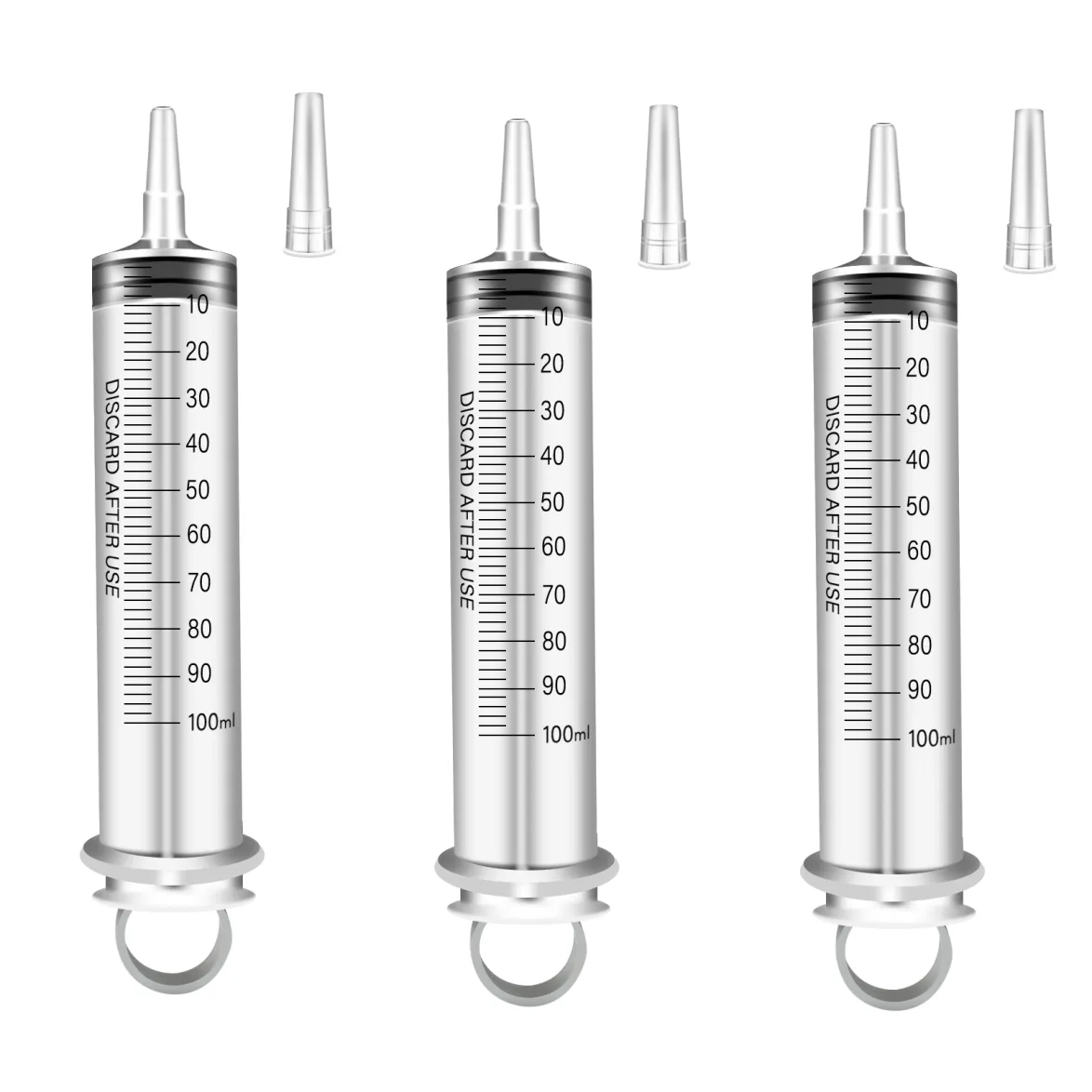

5ml medicine syringe manufacturer

A 5ml medicine syringe manufacturer specializes in producing precise, medical-grade injection devices essential for healthcare applications. These manufacturers employ advanced production technologies and strict quality control measures to ensure each syringe meets international medical standards. The facilities utilize automated production lines equipped with state-of-the-art machinery for molding, assembly, and sterilization processes. The manufacturing process includes high-precision injection molding of medical-grade plastics, automated needle attachment, and comprehensive quality testing protocols. These manufacturers typically maintain ISO 13485 certification and FDA compliance, ensuring their products meet global healthcare requirements. The 5ml capacity is particularly versatile, serving various medical applications from vaccine administration to general medication delivery. The manufacturing process incorporates features such as clear barrel markings, smooth plunger action, and secure needle attachment mechanisms. Modern facilities also implement cleanroom environments and automated inspection systems to maintain product sterility and accuracy. These manufacturers often provide customization options, including different needle sizes, safety features, and packaging configurations to meet specific client requirements.