23 gauge needle and syringe manufacturer

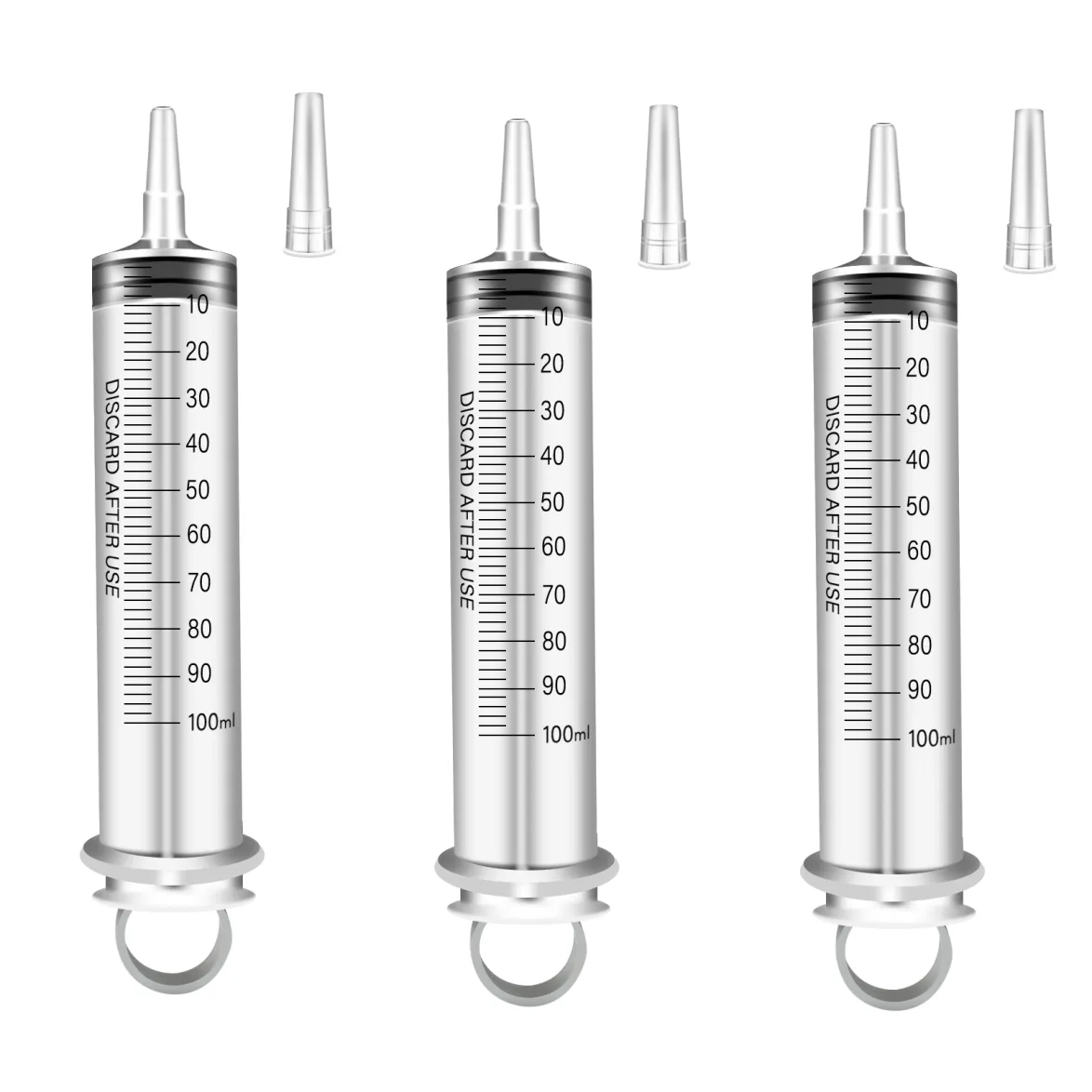

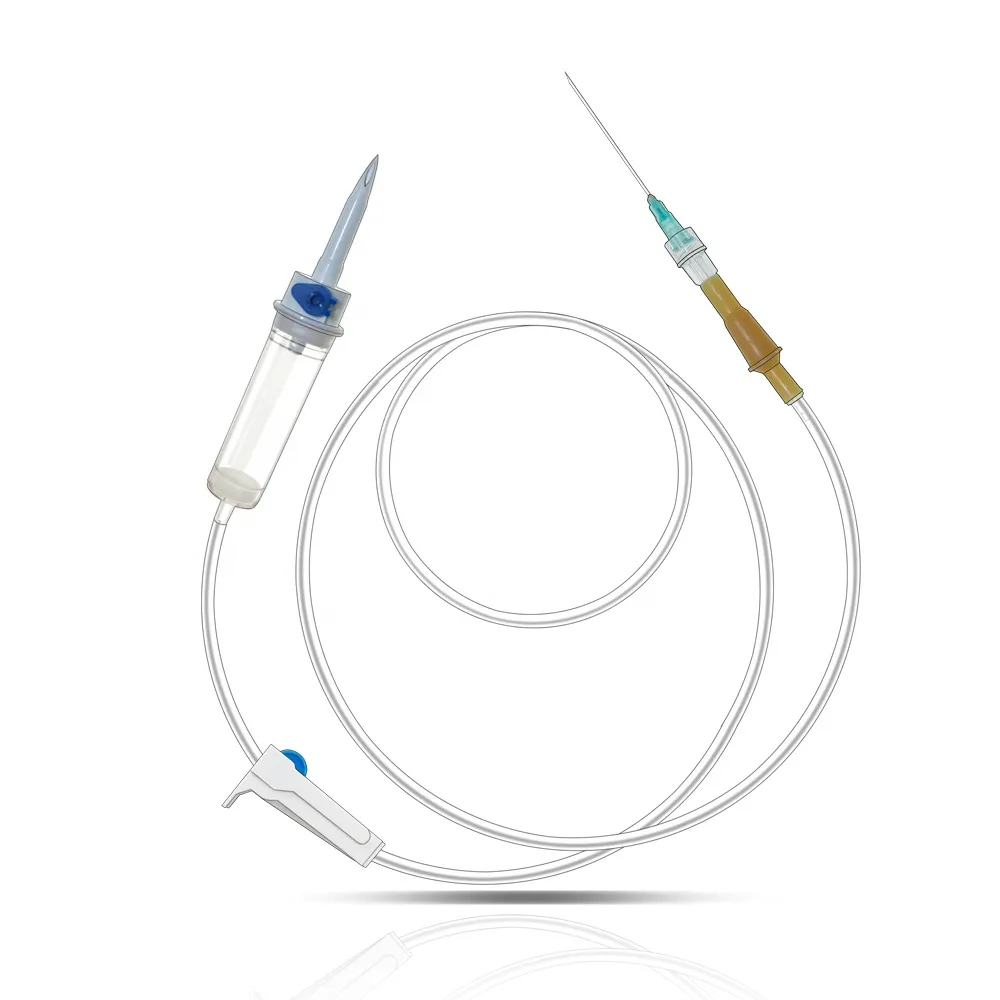

A 23 gauge needle and syringe manufacturer represents a crucial player in the medical device industry, specializing in the production of precision instruments essential for healthcare delivery. These manufacturers employ state-of-the-art manufacturing processes and quality control systems to produce needles that measure 0.6mm in external diameter, striking an optimal balance between patient comfort and effective medication delivery. The facility incorporates advanced automation technology and clean room environments to ensure consistent product quality and sterility. The manufacturing process encompasses multiple stages, from raw material selection and testing to final product sterilization and packaging. The manufacturer's capabilities typically include the production of both conventional and safety-engineered needle designs, complete with various syringe barrel sizes and custom specifications to meet diverse medical applications. Quality assurance protocols adhere to international standards such as ISO 13485 and FDA regulations, ensuring each product meets stringent medical device requirements. The facility's production lines are designed for high-volume output while maintaining precision and consistency in needle specifications, including wall thickness, bevel angle, and surface finish.