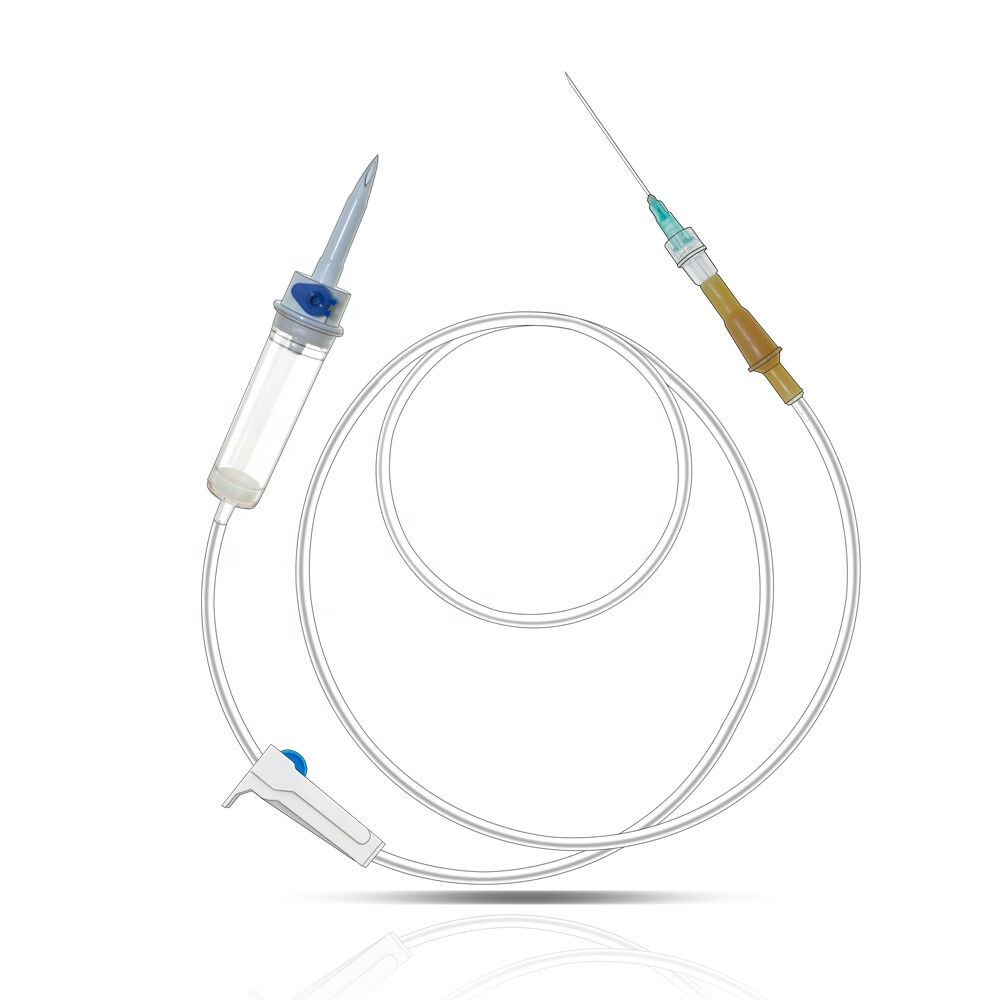

27g 1 inch needle manufacturer

A 27g 1 inch needle manufacturer represents a specialized entity in medical device production, focusing on precision engineering and quality control in creating these essential medical tools. These manufacturers employ state-of-the-art automation systems and quality assurance protocols to produce needles that meet strict medical standards. The production process involves high-grade stainless steel formation, precise grinding techniques, and sophisticated coating applications to ensure optimal performance. The facility maintains ISO 13485 certification and FDA compliance, utilizing clean room environments for manufacturing. The manufacturer's capabilities extend to producing various needle specifications, with the 27g 1 inch configuration being particularly suited for specific medical applications. These needles feature ultra-thin walls, enabling maximum flow rates while maintaining structural integrity. The manufacturing process includes rigorous testing phases, including strength assessment, sharpness verification, and sterilization validation. The facility's production capacity typically ranges from 500,000 to 1 million units monthly, with stringent quality control measures at every stage of manufacturing.