luer lock 1 ml manufacturer

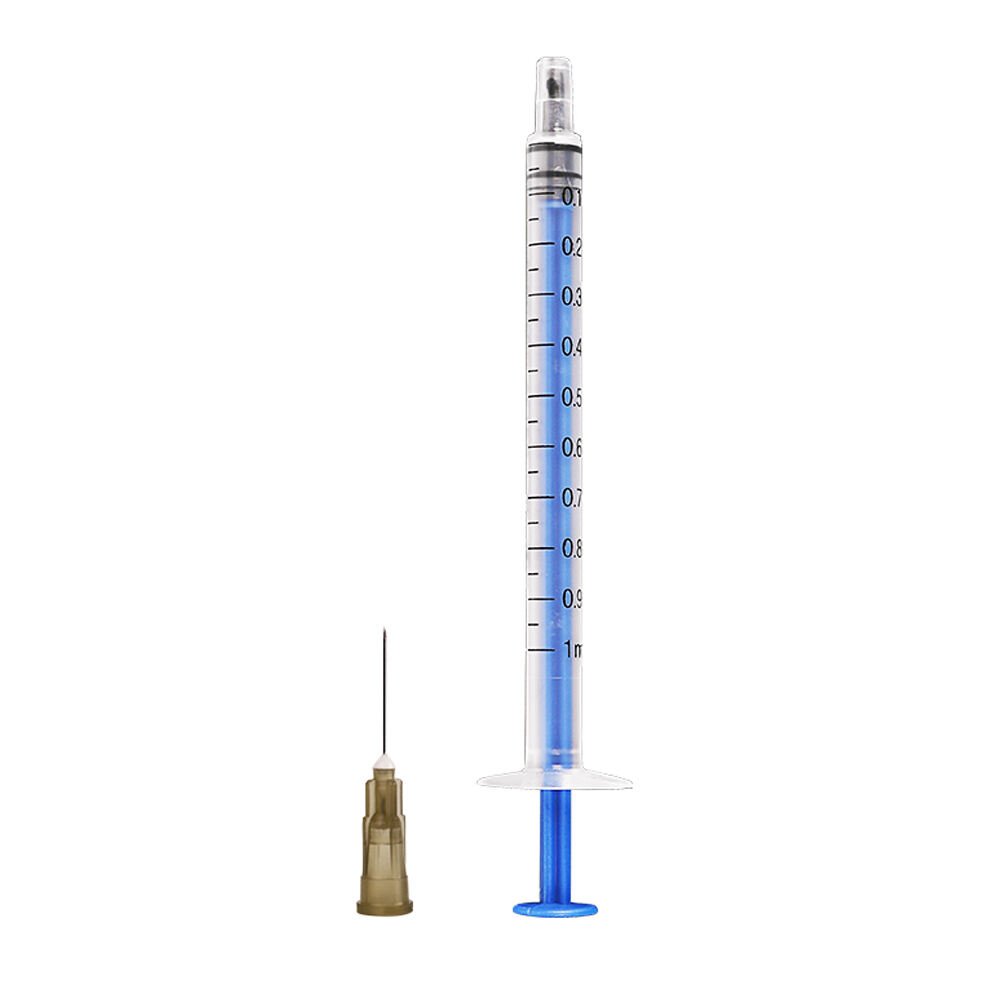

A luer lock 1 ml manufacturer specializes in producing high-precision medical devices designed for accurate fluid delivery in healthcare settings. These manufacturers employ state-of-the-art production facilities equipped with advanced injection molding technology and automated quality control systems to ensure consistent product quality. The manufacturing process adheres to strict ISO 13485 medical device standards and FDA regulations, incorporating clean room environments for contamination-free production. The 1 ml syringes feature precise graduated markings, ensuring accurate dosage measurements, while the luer lock mechanism provides a secure connection to needles and other medical devices. The manufacturing process includes rigorous testing protocols for materials, dimensional accuracy, and functional performance. These manufacturers typically utilize medical-grade polypropylene and other biocompatible materials that meet USP Class VI requirements. The production line incorporates automated visual inspection systems and regular quality audits to maintain product integrity. Many manufacturers also offer customization options, including different barrel lengths, plunger designs, and specialized coating treatments for specific medical applications.