Medical professionals and caregivers understand the critical importance of reliable urinary drainage systems in healthcare settings. A leak-proof urine bag represents an essential medical device that ensures patient comfort, hygiene, and safety during catheterization procedures. These specialized drainage systems have revolutionized patient care by providing secure, sterile collection of urinary output while minimizing the risk of contamination and spillage. Healthcare facilities worldwide rely on these innovative devices to maintain optimal standards of care and patient dignity.

Essential Features of Modern Leak-Proof Urine Bags

Advanced Seal Technology

The foundation of any effective leak-proof urine bag lies in its superior sealing mechanisms. Modern medical-grade bags incorporate multi-layered construction with heat-sealed edges that create an impermeable barrier against fluid leakage. These precision-engineered seals undergo rigorous testing to ensure they maintain integrity under various pressure conditions. The reinforced connection points between the bag and tubing system utilize advanced polymer materials that resist stress fractures and maintain their seal over extended periods of use.

Quality manufacturers employ sophisticated welding techniques that create molecular bonds between materials, resulting in seams stronger than the surrounding bag material itself. This technology ensures that even under maximum capacity conditions, the leak-proof urine bag maintains its structural integrity. The seamless construction eliminates potential weak points that could compromise the containment system, providing healthcare providers with confidence in their drainage solutions.

Material Composition and Durability

Premium leak-proof urine bag systems utilize medical-grade polyethylene and PVC compounds specifically formulated for biocompatibility and strength. These materials resist punctures, tears, and chemical degradation from prolonged contact with bodily fluids. The thickness of the bag walls is carefully calibrated to provide flexibility for patient comfort while maintaining sufficient durability to prevent accidental breaches.

The selection of materials also considers factors such as transparency for visual monitoring, texture for grip during handling, and chemical stability to prevent reactions with medications or cleaning agents. Advanced formulations include antimicrobial additives that help reduce bacterial growth on the bag surface, contributing to overall infection control protocols. This comprehensive approach to material science ensures that each leak-proof urine bag delivers reliable performance throughout its intended use period.

Clinical Benefits and Patient Safety

Infection Prevention and Control

Healthcare-associated infections represent a significant concern in medical facilities, making the sterile design of leak-proof urine bag systems paramount to patient safety. These devices feature closed drainage systems that minimize exposure to environmental contaminants while maintaining sterile pathways for urine collection. The secure sealing mechanisms prevent backflow and cross-contamination, critical factors in preventing urinary tract infections and other complications.

Modern leak-proof urine bag designs incorporate anti-reflux valves and specialized drainage ports that maintain system integrity while allowing for safe emptying procedures. These features work in conjunction with sterile packaging and single-use protocols to create comprehensive infection prevention strategies. Healthcare providers can confidently rely on these systems to support their infection control initiatives while providing optimal patient care.

Enhanced Patient Mobility and Comfort

Patient mobility during treatment significantly impacts recovery outcomes and overall quality of care. A well-designed leak-proof urine bag enables patients to move freely without concern for system failures or embarrassing incidents. The secure attachment mechanisms and flexible tubing configurations accommodate various patient positions and activities while maintaining reliable drainage function.

The psychological benefits of using a dependable leak-proof urine bag cannot be understated, as patients experience reduced anxiety about potential accidents or system malfunctions. This confidence contributes to better patient cooperation with treatment protocols and improved overall satisfaction with their healthcare experience. The discreet design and reliable performance of modern drainage systems help preserve patient dignity throughout their care journey.

Selection Criteria for Healthcare Facilities

Capacity and Size Considerations

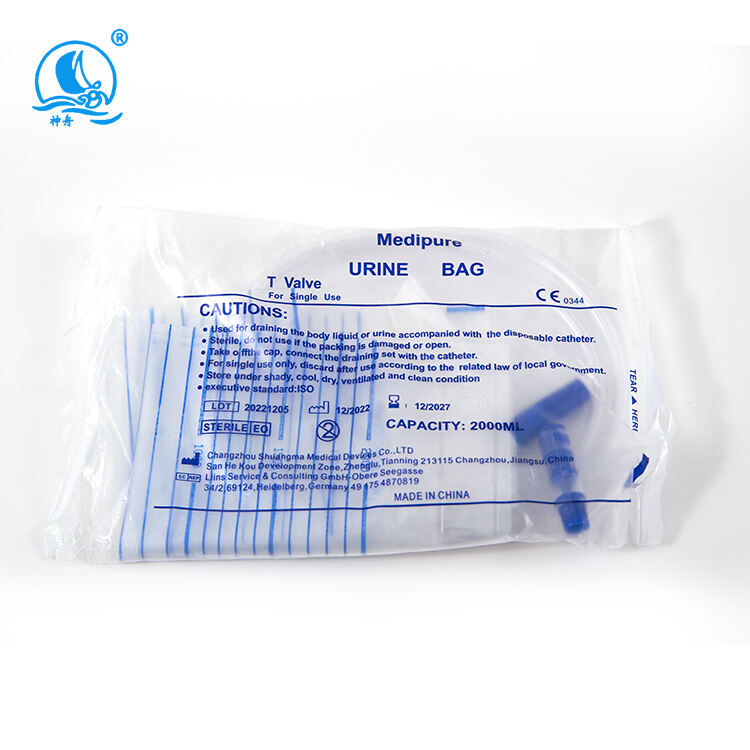

Selecting the appropriate leak-proof urine bag requires careful consideration of patient needs, treatment duration, and facility protocols. Standard capacities range from 350ml for pediatric applications to 2000ml for adult long-term care situations. The choice of bag size directly impacts the frequency of emptying procedures and overall system maintenance requirements, making proper selection crucial for operational efficiency.

Healthcare facilities must also consider the physical dimensions of the leak-proof urine bag in relation to patient mobility requirements and bed configurations. Larger capacity bags may limit patient movement but reduce nursing intervention frequency, while smaller bags offer greater mobility at the cost of more frequent maintenance. The optimal selection balances these competing factors based on individual patient circumstances and care objectives.

Compatibility and Integration

Modern healthcare facilities utilize diverse catheter systems and drainage equipment, making compatibility a critical factor in leak-proof urine bag selection. Universal connection standards ensure seamless integration with existing catheter types and drainage tubing, eliminating compatibility concerns that could compromise patient care. The standardization of connections also reduces inventory complexity and staff training requirements.

Integration considerations extend beyond physical connections to include compatibility with electronic monitoring systems, bed-mounted drainage stands, and portable collection devices. A comprehensive leak-proof urine bag system should accommodate these various configurations without requiring additional adapters or modifications that could introduce potential failure points or compromise system integrity.

Quality Assurance and Regulatory Compliance

Manufacturing Standards and Certifications

The production of medical-grade leak-proof urine bag systems requires adherence to stringent manufacturing standards and regulatory requirements. ISO 13485 certification ensures that manufacturers maintain comprehensive quality management systems throughout the production process, from raw material selection to final packaging. These standards mandate rigorous testing protocols, documentation procedures, and continuous improvement processes that guarantee product consistency and reliability.

Regulatory compliance extends to material safety, biocompatibility testing, and sterility validation procedures that verify each leak-proof urine bag meets established safety standards. Third-party testing laboratories conduct independent verification of product performance, including leak testing, durability assessments, and chemical compatibility evaluations. This multi-layered approach to quality assurance provides healthcare facilities with confidence in their drainage system selections.

Performance Testing and Validation

Comprehensive performance testing protocols evaluate every aspect of leak-proof urine bag functionality under simulated clinical conditions. These tests include pressure resistance assessments, seal integrity verification, and long-term durability studies that simulate extended use scenarios. Manufacturers conduct accelerated aging tests to predict product performance over time and identify potential failure modes before products reach clinical settings.

Validation procedures also encompass real-world clinical testing in controlled healthcare environments, where leak-proof urine bag systems undergo evaluation under actual use conditions. This clinical validation provides valuable data on product performance, user satisfaction, and potential areas for improvement. The combination of laboratory testing and clinical validation ensures that each product meets the demanding requirements of modern healthcare applications.

Economic Considerations and Cost-Effectiveness

Total Cost of Ownership Analysis

Healthcare administrators must evaluate the complete economic impact of leak-proof urine bag selection beyond initial purchase costs. Total cost of ownership includes factors such as nursing time for system changes, infection prevention benefits, and potential liability reduction associated with reliable drainage systems. Higher-quality leak-proof urine bag systems often provide superior cost-effectiveness through reduced complication rates and improved operational efficiency.

The economic benefits of investing in premium leak-proof urine bag systems extend to reduced laundry costs, decreased environmental cleanup requirements, and improved patient satisfaction scores that can impact facility reimbursement rates. Long-term analysis reveals that initial cost savings from lower-quality products often result in higher total expenses due to increased complication rates and operational inefficiencies.

Inventory Management and Procurement

Effective inventory management strategies for leak-proof urine bag systems require careful balance between cost optimization and service level maintenance. Bulk purchasing agreements can provide significant cost savings while ensuring adequate stock levels for continuous patient care. However, facilities must also consider storage requirements, expiration date management, and product standardization benefits when developing procurement strategies.

Strategic partnerships with reliable suppliers enable healthcare facilities to implement just-in-time delivery systems that reduce inventory carrying costs while maintaining service levels. These relationships also provide access to technical support, training resources, and product updates that enhance overall system performance and staff competency in leak-proof urine bag utilization.

FAQ

What makes a urine bag truly leak-proof?

A truly leak-proof urine bag incorporates multiple sealing technologies including heat-welded seams, reinforced connection points, and anti-reflux valves. The bag material itself must be manufactured from medical-grade polymers that resist punctures and chemical degradation. Quality control testing ensures each unit maintains seal integrity under pressure conditions that exceed normal clinical use scenarios.

How often should leak-proof urine bags be changed?

Most leak-proof urine bag systems are designed for single-use applications and should be changed according to facility protocols, typically every 5-7 days for standard drainage bags or more frequently if contamination is suspected. The specific change frequency depends on patient condition, facility infection control policies, and manufacturer recommendations. Regular assessment of bag condition and drainage quality helps determine optimal change intervals.

Can leak-proof urine bags be used with all catheter types?

Modern leak-proof urine bag systems feature universal connection designs compatible with most standard catheter types including Foley catheters, suprapubic catheters, and external collection devices. However, healthcare providers should verify compatibility specifications before use and ensure proper connection techniques are followed. Some specialty applications may require specific bag configurations or adapter components.

What should healthcare staff do if a leak-proof urine bag fails?

If a leak-proof urine bag experiences failure, immediate replacement with a new sterile unit is essential to maintain patient safety and infection control. Staff should document the failure incident, preserve the failed unit for quality assurance review, and follow facility protocols for product defect reporting. Proper disposal of contaminated materials and environmental cleanup procedures must be implemented promptly to prevent cross-contamination.