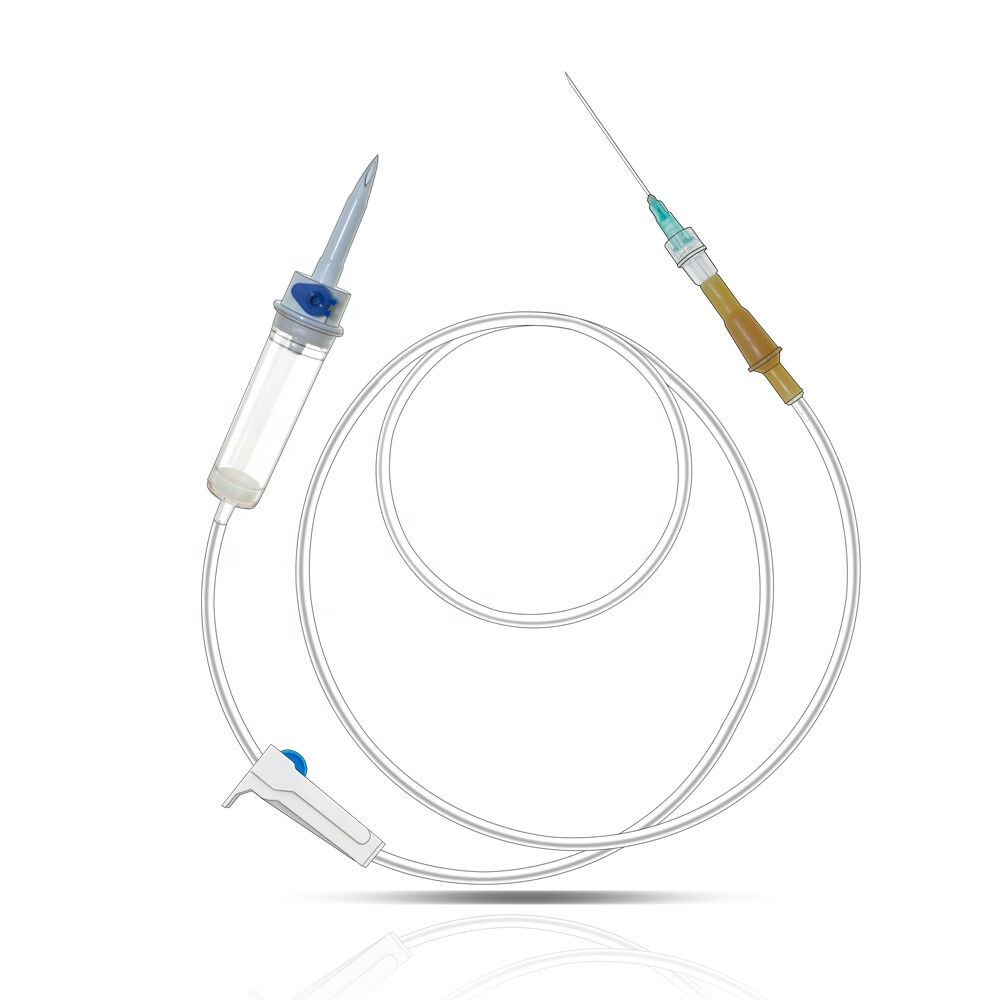

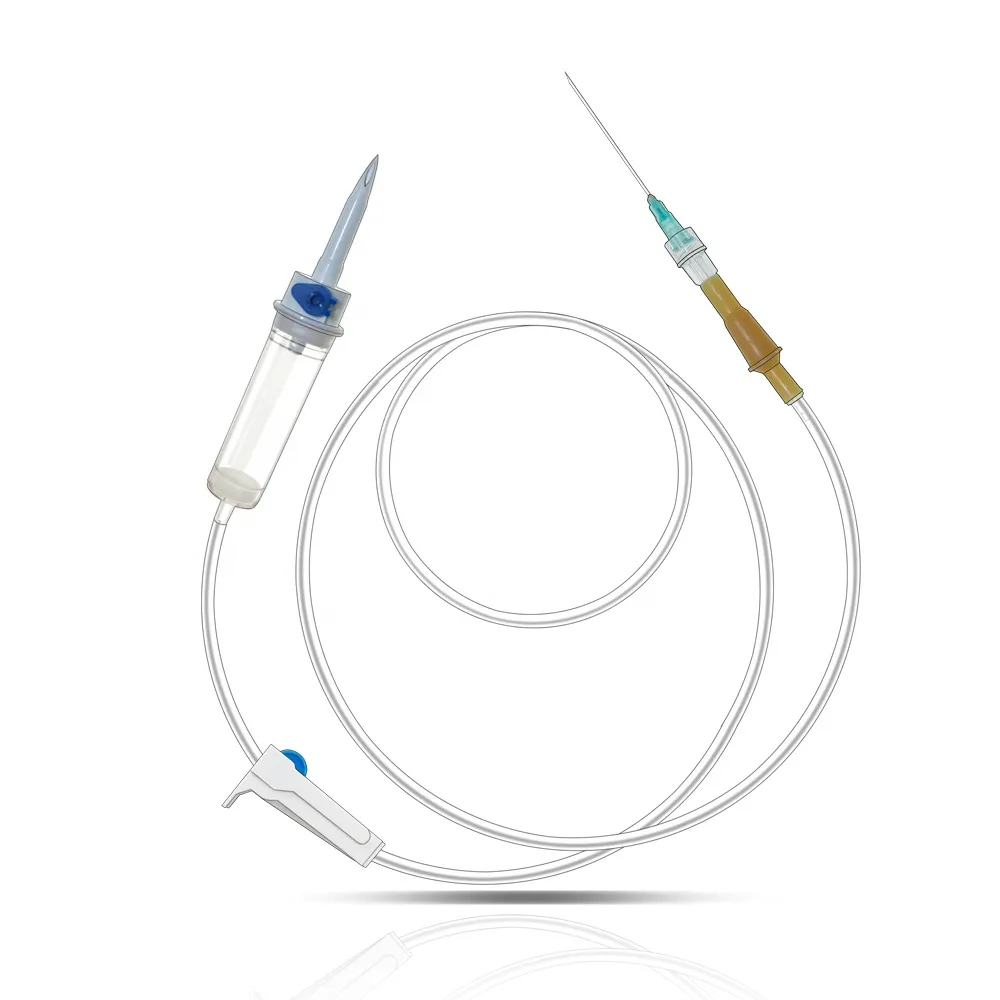

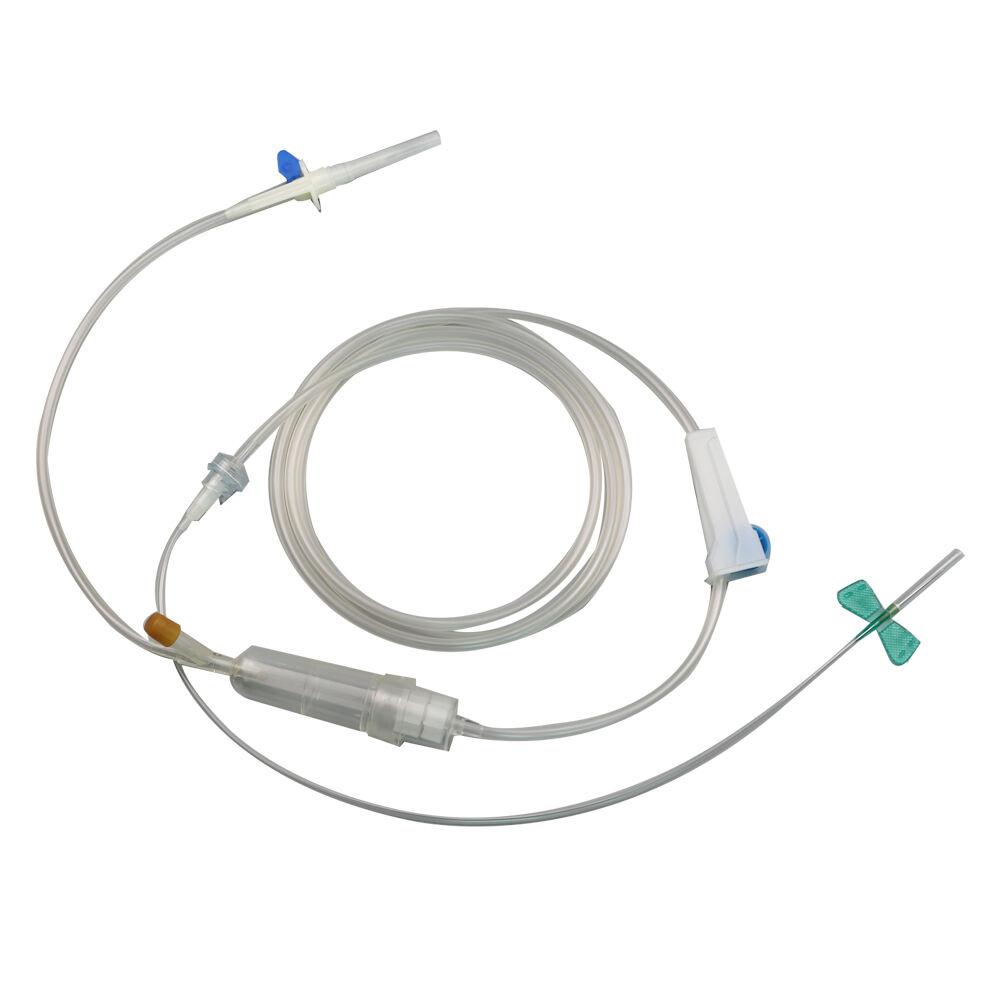

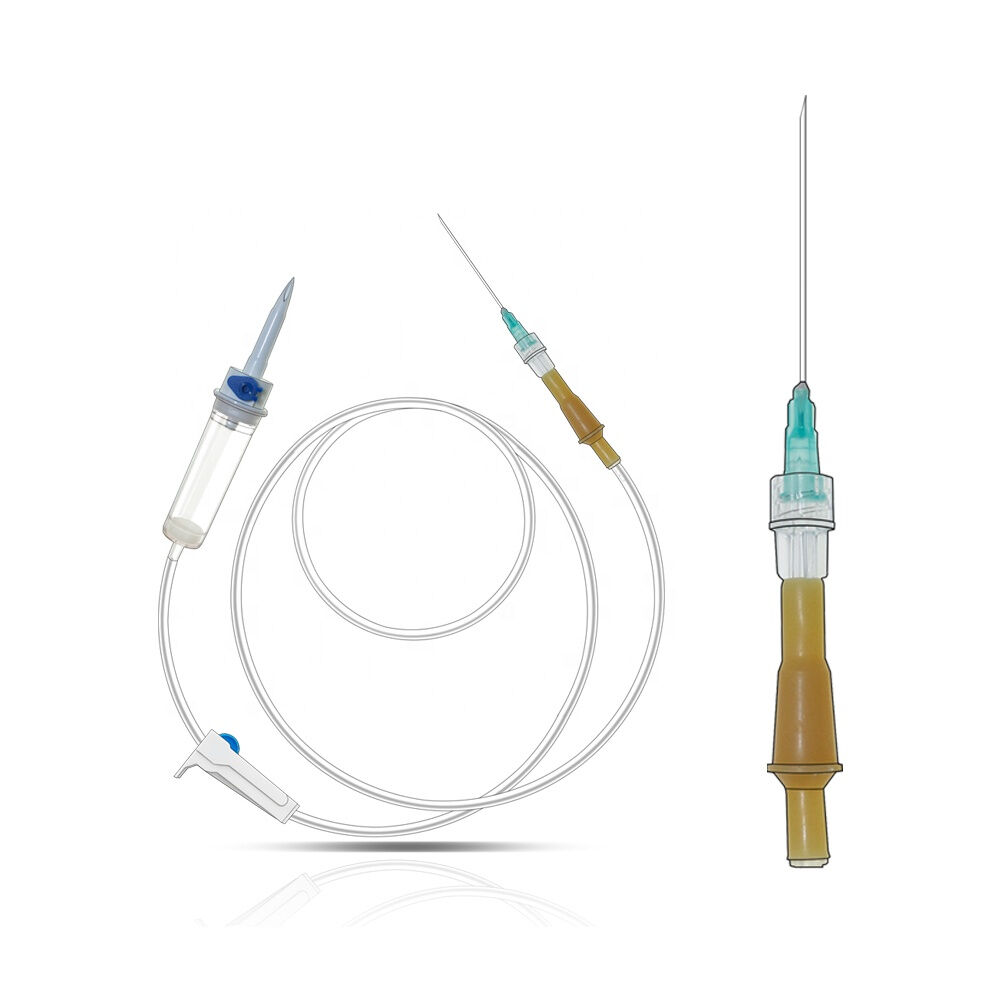

disposable infusion set manufacturer

A disposable infusion set manufacturer specializes in producing high-quality, single-use medical devices essential for delivering fluids, medications, and nutrients directly into a patient's bloodstream. These manufacturers employ state-of-the-art production facilities equipped with advanced clean room technology and automated assembly lines to ensure consistent quality and sterility. The manufacturing process incorporates precision engineering in the design of components such as needles, tubing, flow regulators, and connection ports. Modern facilities utilize advanced quality control systems, including automated visual inspection and rigorous testing protocols, to maintain compliance with international medical device standards. The manufacturer's capabilities typically extend to producing various infusion set types, from gravity-driven systems to specialized sets compatible with electronic infusion pumps. They implement strict material selection processes, choosing medical-grade polymers and surgical-quality stainless steel to ensure biocompatibility and patient safety. The production line includes innovative features such as air-elimination filters, precise flow control mechanisms, and safety devices to prevent needlestick injuries. These manufacturers also maintain comprehensive documentation systems for traceability and regulatory compliance, ensuring each product meets the highest standards of medical device manufacturing.