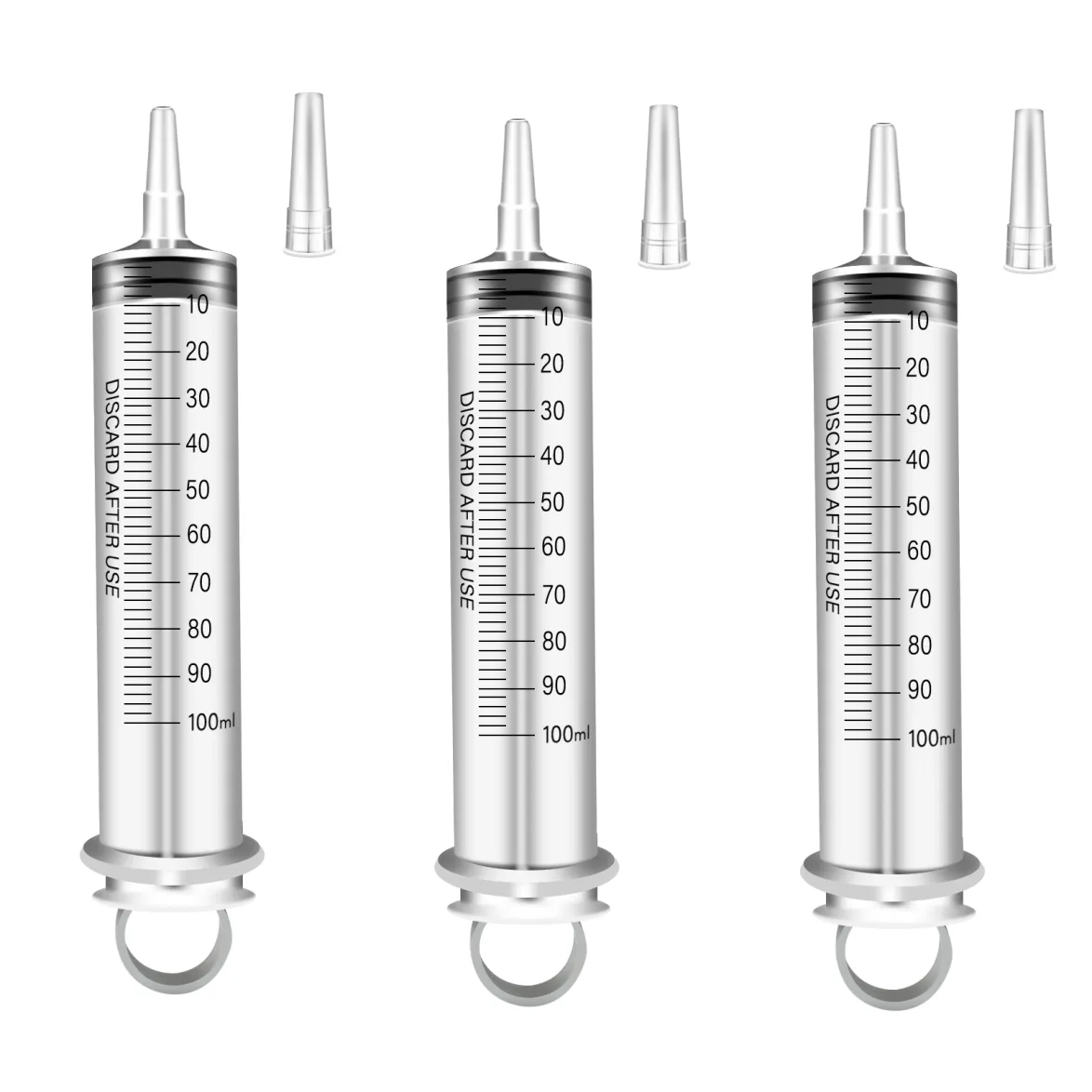

disposable injection syringe manufacturer

A disposable injection syringe manufacturer specializes in producing high-quality, single-use medical devices essential for safe and sterile medication administration. These facilities employ advanced automation systems and precision engineering to create syringes that meet strict medical standards and regulatory requirements. The manufacturing process incorporates state-of-the-art clean room technology, ensuring products are free from contaminants and suitable for medical use. These facilities typically utilize medical-grade materials, primarily polypropylene and rubber, processed through sophisticated injection molding systems. The production line includes multiple quality control checkpoints, from raw material testing to final product inspection, ensuring each syringe meets exact specifications for safety and reliability. Modern manufacturers integrate computer-controlled assembly systems that guarantee precise measurements and consistent quality across production batches. The facilities also implement comprehensive tracking systems for quality assurance and regulatory compliance, allowing for complete product traceability from manufacture to distribution. Advanced sterilization processes, typically using ethylene oxide or gamma radiation, ensure each syringe maintains sterility until use. These manufacturing operations often maintain ISO 13485 certification and comply with FDA requirements, demonstrating their commitment to quality medical device production.