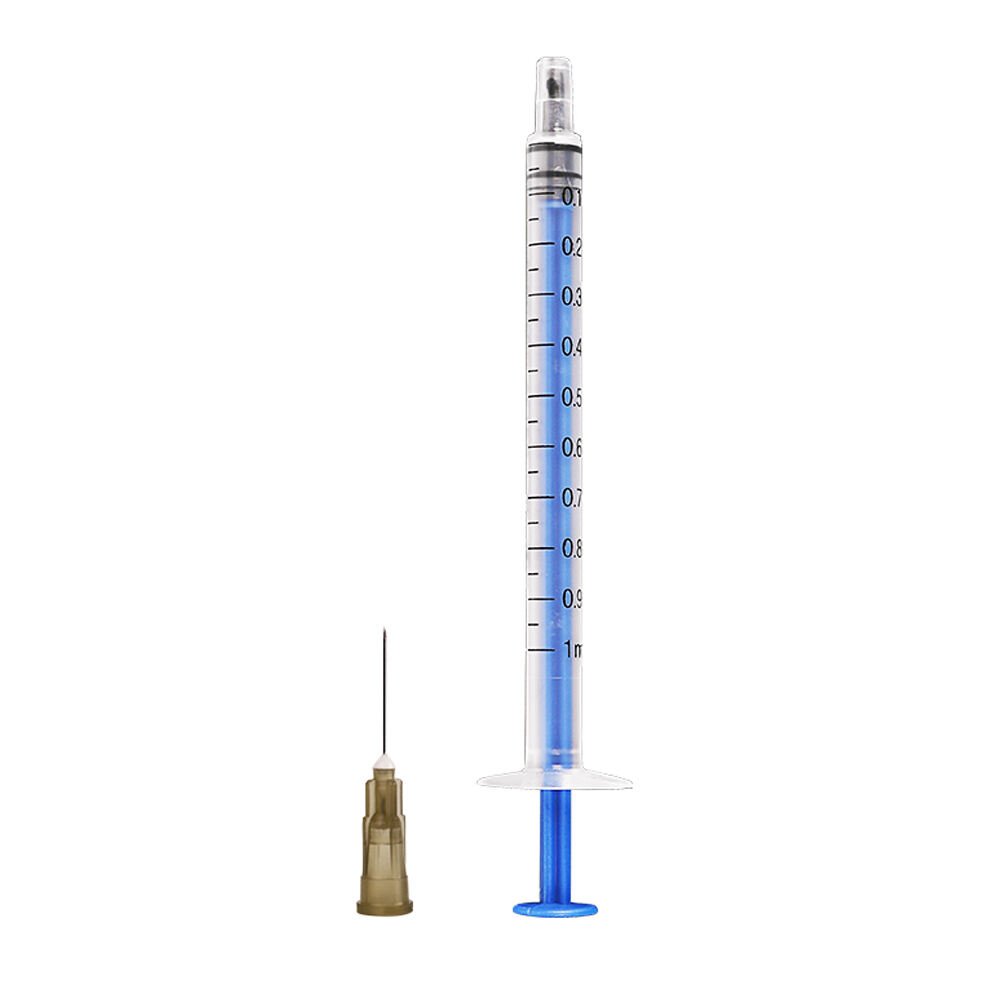

1cc syringe with needle manufacturer

A 1cc syringe with needle manufacturer specializes in producing precision medical devices essential for accurate medication delivery and vaccination processes. These manufacturers employ state-of-the-art production facilities equipped with advanced clean room technology and automated assembly lines to ensure consistent quality and sterility. The manufacturing process incorporates medical-grade materials, including high-quality polypropylene for the barrel and specialized stainless steel for needles, meeting stringent international standards such as ISO 13485 and FDA requirements. The production encompasses various needle specifications, including different gauge sizes and lengths, to accommodate diverse medical applications. Quality control measures include rigorous testing for needle sharpness, smooth plunger movement, and precise graduations ensuring accurate dosing. Modern manufacturers implement sophisticated sterilization processes, typically using ethylene oxide or gamma radiation, to guarantee product safety. Additionally, these facilities often feature advanced packaging solutions that maintain product integrity throughout storage and transportation. The manufacturing process also emphasizes environmental responsibility through waste reduction and energy-efficient operations.