Na saúde moderna, a qualidade dos dispositivos médicos impacta diretamente a segurança do paciente e os resultados do tratamento. Entre os componentes mais críticos na terapia intravenosa está o conjunto IV, que atua como a conexão vital entre os sistemas de administração de medicamentos e os pacientes. Profissionais de saúde em todo o mundo reconhecem que a escolha de um conjunto IV de alta qualidade não é meramente uma decisão de aquisição, mas um compromisso fundamental com a excelência no cuidado ao paciente. A importância dessa escolha vai além da funcionalidade imediata, abrangendo a segurança do paciente a longo prazo, a relação custo-benefício e as taxas gerais de sucesso terapêutico.

A indústria da saúde testemunhou avanços notáveis em equipamentos para terapia intravenosa, mas os princípios fundamentais de qualidade e confiabilidade permanecem primordiais. Instalações médicas de diferentes especialidades, desde departamentos de emergência até salas cirúrgicas, dependem do desempenho consistente de seus sistemas de infusão intravenosa. Compreender as características que distinguem conjuntos IV superiores das alternativas padrão permite que administradores de saúde e equipes clínicas tomem decisões informadas que, em última instância, beneficiam os resultados dos pacientes e a eficiência operacional.

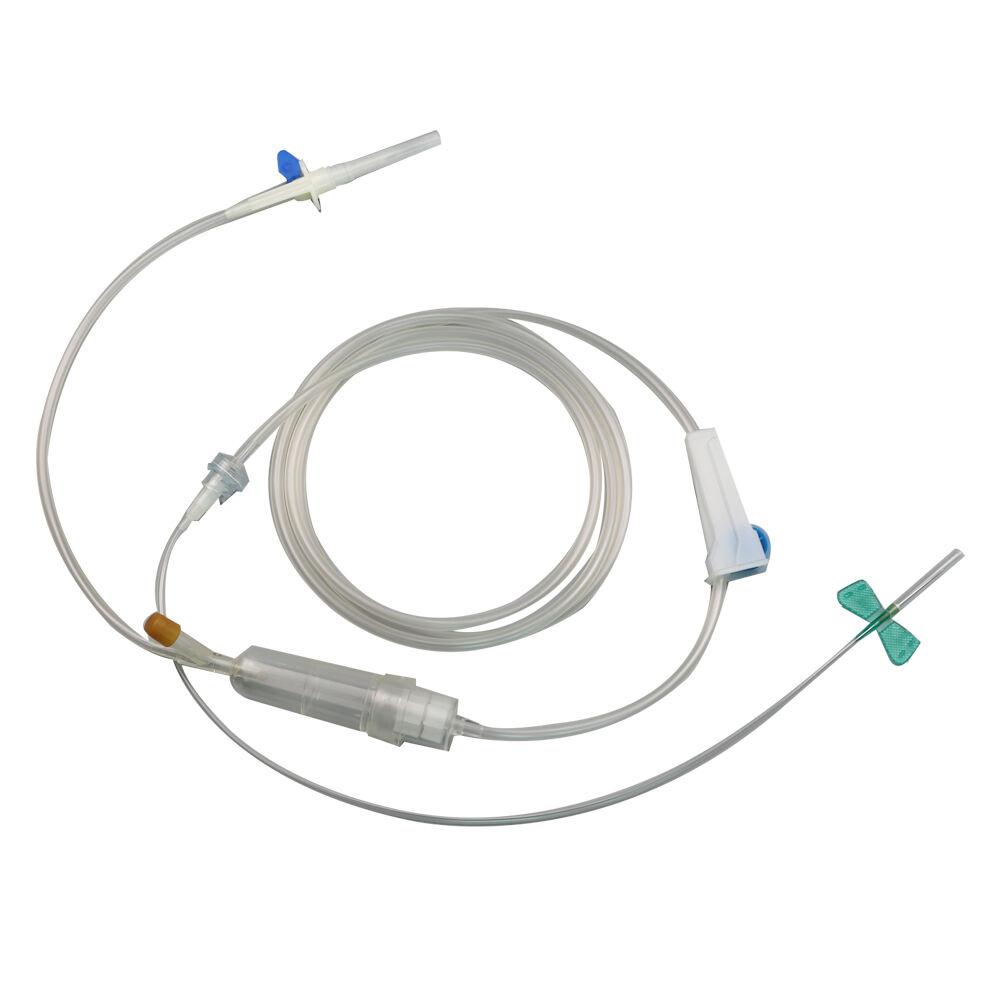

Componentes Essenciais e Características de Projeto

Tecnologia Avançada de Câmara de Gotejamento

A câmara de gotejamento representa um dos componentes mais críticos em qualquer configuração de conjunto de soro. Câmaras de gotejamento de alta qualidade possuem engenharia precisa que garante uma visualização exata do fluxo e dinâmica ideal de fluidos. Essas câmaras incorporam mecanismos anti-refluxo que evitam a contaminação por refluxo, mantendo a esterilidade durante todo o processo de infusão. Os materiais transparentes utilizados nas câmaras de gotejamento premium são submetidos a testes rigorosos para garantir clareza e durabilidade sob diversas condições clínicas.

Os designs modernos de câmara de gotejamento também incorporam considerações ergonômicas que facilitam o manuseio pelos profissionais de saúde durante os procedimentos de instalação e monitoramento. As dimensões da câmara são cuidadosamente calculadas para proporcionar uma formação ideal das gotas, permitindo a avaliação precisa da taxa de fluxo por meio de inspeção visual. Essa precisão no design é particularmente crucial em ambientes de cuidados intensivos, onde a exatidão na dosagem de medicamentos pode impactar significativamente os resultados para o paciente.

Qualidade e Flexibilidade da Tubulação

O material da tubulação e a metodologia de construção influenciam diretamente o desempenho geral e a durabilidade de um conjunto IV. Fabricantes premium utilizam PVC de grau médico ou outros materiais biocompatíveis que resistem a dobramentos, rachaduras e degradação sob uso clínico normal. A consistência do diâmetro interno ao longo do comprimento da tubulação garante taxas de fluxo previsíveis e minimiza variações de pressão que poderiam afetar o tempo de administração de medicamentos.

As características de flexibilidade desempenham um papel crucial na usabilidade clínica, especialmente em cenários de cuidados ao paciente onde movimentos e mudanças de posicionamento são frequentes. A tubulação de alta qualidade mantém sua flexibilidade em uma ampla faixa de temperatura, ao mesmo tempo que oferece integridade estrutural suficiente para prevenir desconexões acidentais ou danos durante o transporte ou reposicionamento do paciente.

Recursos de Segurança e Prevenção de Contaminação

Sistemas de Garantia de Esterilidade

Manter a esterilidade em todo o percurso de administração do medicamento representa um requisito fundamental de segurança para qualquer conjunto IV. Fabricantes premium implementam programas abrangentes de garantia de esterilidade que começam com a seleção das matérias-primas e se estendem até os processos finais de embalagem. Esses programas incluem tipicamente esterilização por gama ou tratamento com óxido de etileno, seguidos de protocolos rigorosos de testes para verificar a manutenção da esterilidade durante períodos prolongados de armazenamento.

O design da embalagem para conjuntos IV de alta qualidade incorpora múltiplas camadas de barreira que protegem contra contaminação microbiana, ao mesmo tempo que oferecem recursos de fácil abertura para a equipe clínica. Selos com evidência de violação e marcação clara da data de validade asseguram que os profissionais de saúde possam verificar rapidamente a integridade do produto antes do uso. Essas medidas de segurança tornam-se particularmente importantes em ambientes clínicos de alto volume, onde a implantação rápida é essencial.

Segurança de Conexão e Sistemas Luer Lock

Conexões seguras entre os componentes do conjunto IV evitam desconexões acidentais que poderiam levar à perda de medicamento, embolia aérea ou eventos de contaminação. Conjuntos IV premium utilizam mecanismos luer lock projetados com precisão que garantem engajamento confiável, ao mesmo tempo que permitem desconexão fácil quando necessário. As especificações de rosca e requisitos de torque são padronizados para assegurar compatibilidade com diversos dispositivos médicos e acessórios.

O design do ponto de conexão também incorpora características que minimizam o volume de espaço morto, reduzindo o desperdício de medicamento e melhorando a precisão da dosagem para medicamentos de alta potência. Os materiais utilizados nos componentes de conexão resistem à degradação causada por agentes de limpeza e desinfetantes comumente usados em ambientes de saúde, garantindo desempenho seguro e confiável a longo prazo.

Mecanismos de Controle e Regulação de Fluxo

Pinças Rolantes de Precisão

As capacidades de regulação de fluxo distinguem os conjuntos IV de alta qualidade das alternativas básicas por meio da incorporação de grampos roletes projetados com precisão. Esses mecanismos proporcionam aos profissionais de saúde um controle fino sobre as taxas de infusão, permitindo a administração precisa de medicamentos conforme os protocolos prescritos. O design do grampo evita danos ao tubo durante ajustes repetidos, mantendo uma compressão consistente ao longo da circunferência do tubo.

Os grampos roletes premium apresentam características de operação suave que permitem ajustes graduais na taxa de fluxo, sem alterações bruscas que possam afetar o conforto do paciente ou a eficácia do medicamento. Os materiais utilizados na construção dos grampos resistem à fadiga e ao desgaste, garantindo desempenho confiável durante todo o período de uso previsto para o produto. Essas características tornam-se particularmente valiosas em aplicações pediátricas e em cuidados críticos, onde o controle preciso do fluxo é essencial.

Acessibilidade do Porto de Injeção

Moderno Conjunto iv os designs incorporam portas de injeção estrategicamente posicionadas que facilitam a administração de medicamentos sem comprometer a integridade do sistema. Essas portas utilizam membranas auto-selantes que mantêm a esterilidade após múltiplas punções, ao mesmo tempo em que proporcionam baixa força de inserção para o conforto do profissional de saúde. O posicionamento das portas permite fácil acesso durante as atividades de cuidado ao paciente, sem interferir na gestão dos tubos ou no monitoramento do fluxo.

Portas de injeção de alta qualidade também apresentam guias para agulhas que ajudam a garantir o ângulo e profundidade adequados de inserção, reduzindo o risco de punções completas que poderiam comprometer a integridade do sistema. Os materiais das membranas são selecionados pela compatibilidade com diferentes calibres de agulhas e tipos de medicamentos, assegurando versatilidade em diversas aplicações clínicas e protocolos de tratamento.

Aplicações Clínicas e Considerações Especializadas

Requisitos de Medicina de Emergência

Ambientes médicos de emergência impõem exigências únicas ao desempenho dos conjuntos de soro, exigindo capacidade de implantação rápida e funcionamento confiável em condições de alto estresse. Conjuntos de soro de alta qualidade projetados para uso em emergências incorporam características como embalagem de abertura fácil, identificação clara dos componentes e procedimentos simplificados de montagem, que permitem o rápido estabelecimento do acesso intravenoso. Os materiais e métodos de construção devem suportar o manuseio rigoroso típico em situações de emergência, mantendo ao mesmo tempo a esterilidade e a integridade funcional.

Aplicações de emergência também se beneficiam de conjuntos de soro que incluem múltiplos portos de injeção e possibilidade de extensão, permitindo a administração simultânea de medicamentos e coleta de sangue sem interrupção do sistema. As características da taxa de fluxo devem acomodar protocolos de ressuscitação rápida com fluidos, ao mesmo tempo em que oferecem controle suficiente para transições para terapia de manutenção à medida que as condições do paciente se estabilizam.

Aplicações em Centro Cirúrgico

Ambientes de sala cirúrgica exigem conjuntos de soro que mantenham a esterilidade em condições de uso prolongado, ao mesmo tempo que garantem uma administração confiável de medicamentos durante procedimentos cirúrgicos longos. Conjuntos cirúrgicos de alta qualidade frequentemente incorporam tubos de comprimento alongado, acomodando mudanças na posição do paciente e arranjos de equipamentos comuns em ambientes cirúrgicos. Os materiais devem resistir à degradação causada pela luz cirúrgica, variações de temperatura e agentes de limpeza utilizados em ambientes estéreis.

Aplicações cirúrgicas também exigem conjuntos de soro com geração mínima de partículas e níveis baixos de substâncias extraíveis, para evitar contaminação do campo cirúrgico ou da corrente sanguínea do paciente. Os sistemas de conexão devem proporcionar encaixe seguro que permaneça estável durante movimentações e posicionamento do paciente, ao mesmo tempo que permitem desconexão rápida, caso seja necessário acesso de emergência.

Padrões de Qualidade e Conformidade Regulatória

Normas Internacionais de Fabricação

Fabricantes premium de conjuntos IV aderem a rigorosas normas internacionais de qualidade que regulam a seleção de materiais, processos de fabricação e testes do produto final. A certificação ISO 13485 garante que os sistemas de gestão da qualidade atendam aos requisitos para dispositivos médicos durante todo o ciclo de produção. Essas normas exigem documentação abrangente, validação de processos e programas de melhoria contínua que aumentam a confiabilidade e o desempenho em segurança do produto.

A conformidade com normas farmacopeicas, como os testes USP Classe VI, assegura que os materiais utilizados na construção dos conjuntos IV atendam aos requisitos de biocompatibilidade para contato prolongado com tecidos humanos e fluidos corporais. Esses protocolos de teste avaliam citotoxicidade, potencial de sensibilização e toxicidade sistêmica para verificar a segurança do paciente em condições normais de uso.

Processos de Aprovação Regulatória

A aprovação regulamentar de agências como a FDA, as autoridades responsáveis pela marcação CE e outras autoridades nacionais de saúde garante que os conjuntos IV atendam aos requisitos estabelecidos de segurança e eficácia. O processo de aprovação inclui uma análise abrangente dos dados de fabricação, resultados de testes clínicos e documentação do sistema de qualidade. Essa supervisão regulamentar assegura que os produtos que chegam aos mercados de saúde tenham passado por uma avaliação rigorosa e atendam aos critérios de desempenho estabelecidos.

Os requisitos de vigilância pós-comercialização exigem o monitoramento contínuo do desempenho do produto e a notificação de eventos adversos, fornecendo feedback constante para a melhoria do produto e aprimoramento da segurança. Essas estruturas regulamentares garantem que quaisquer preocupações com a segurança sejam prontamente tratadas e que as modificações nos produtos sejam adequadamente validadas antes da implementação.

Considerações Econômicas e Custo-Efetividade

Análise do Custo Total de Propriedade

Embora conjuntos IV de alta qualidade possam envolver custos iniciais mais altos de aquisição, uma análise abrangente de custos geralmente revela um valor superior por meio da redução de complicações, menores falhas de produto e melhores resultados para o paciente. O custo total de propriedade inclui fatores como confiabilidade do produto, requisitos de treinamento da equipe, eficiência na gestão de inventário e exposição potencial a responsabilidades relacionadas a problemas de desempenho do produto.

Conjuntos IV premium normalmente demonstram maior vida útil, requisitos reduzidos de armazenamento e taxas mais baixas de defeitos, o que se traduz em economia operacional ao longo do tempo. A maior confiabilidade reduz a necessidade de substituição emergencial de produtos e minimiza atrasos no tratamento que poderiam afetar a satisfação do paciente e a eficiência do fluxo de trabalho clínico.

Valor de Mitigação de Riscos

Investir em conjuntos de IV de alta qualidade oferece um valor significativo de mitigação de riscos, reduzindo a probabilidade de complicações como infecções, erros medicamentosos ou falhas no dispositivo. Essa redução de riscos se traduz em prêmios mais baixos para seguros contra má prática, menos autuações regulatórias e melhores pontuações de segurança do paciente, o que melhora a reputação institucional e o status de acreditação.

Os recursos de documentação e rastreabilidade incorporados nos conjuntos de IV premium também facilitam a conformidade com iniciativas de melhoria da qualidade e requisitos regulatórios, reduzindo a carga administrativa e os custos de preparação para auditorias. Esses recursos tornam-se particularmente valiosos em ambientes de saúde onde a precisão e completude da documentação são essenciais para reembolsos e relatórios de qualidade.

Perguntas Frequentes

O que torna um conjunto de IV de alta qualidade em comparação com opções padrão

Conjuntos IV de alta qualidade destacam-se por materiais superiores, fabricação precisa, recursos avançados de segurança e testes abrangentes de controle de qualidade. Esses produtos utilizam materiais de grau médico que resistem à degradação, incorporam características de design avançado como mecanismos anti-refluxo e passam por rigorosa validação de esterilidade. Os processos de fabricação seguem rigorosas normas internacionais, garantindo desempenho e confiabilidade consistentes em todos os lotes do produto.

Como determinar o conjunto IV apropriado para aplicações clínicas específicas

A seleção do conjunto IV apropriado exige considerar fatores como a população de pacientes, tipos de medicamentos, duração da infusão e requisitos do ambiente clínico. Ambientes de emergência se beneficiam de designs de implantação rápida com múltiplas portas, enquanto aplicações cirúrgicas exigem comprimentos maiores e maior garantia de esterilidade. O uso pediátrico exige mecanismos precisos de controle de fluxo, e os ambientes de cuidados críticos necessitam de sistemas de conexão confiáveis que resistam à manipulação frequente.

Quais certificações de segurança devo procurar ao comprar conjuntos IV

As certificações essenciais incluem a ISO 13485 para sistemas de gestão da qualidade, USP Classe VI para testes de biocompatibilidade e aprovações regulamentares de autoridades competentes, como a liberação pela FDA ou marcação CE. Outras certificações podem incluir a ISO 10993 para avaliação biológica e conformidade com farmacopeias específicas, dependendo dos requisitos regionais. Essas certificações garantem que os produtos atendam aos padrões estabelecidos de segurança e desempenho.

Como os conjuntos IV de alta qualidade impactam os custos gerais com saúde

Conjuntos IV de alta qualidade geralmente reduzem os custos globais com saúde por meio de maior confiabilidade, menos complicações e eficiência operacional aprimorada. Embora os custos iniciais de aquisição possam ser mais altos, a menor incidência de falhas no dispositivo, infecções e atrasos no tratamento normalmente resulta em economia líquida de custos. Além disso, produtos premium frequentemente incluem recursos que agilizam os fluxos de trabalho clínicos, reduzem os requisitos de treinamento da equipe e minimizam a complexidade na gestão de estoque, contribuindo para a redução geral dos custos operacionais.

Sumário

- Componentes Essenciais e Características de Projeto

- Recursos de Segurança e Prevenção de Contaminação

- Mecanismos de Controle e Regulação de Fluxo

- Aplicações Clínicas e Considerações Especializadas

- Padrões de Qualidade e Conformidade Regulatória

- Considerações Econômicas e Custo-Efetividade

-

Perguntas Frequentes

- O que torna um conjunto de IV de alta qualidade em comparação com opções padrão

- Como determinar o conjunto IV apropriado para aplicações clínicas específicas

- Quais certificações de segurança devo procurar ao comprar conjuntos IV

- Como os conjuntos IV de alta qualidade impactam os custos gerais com saúde