disposable needle syringe manufacturer

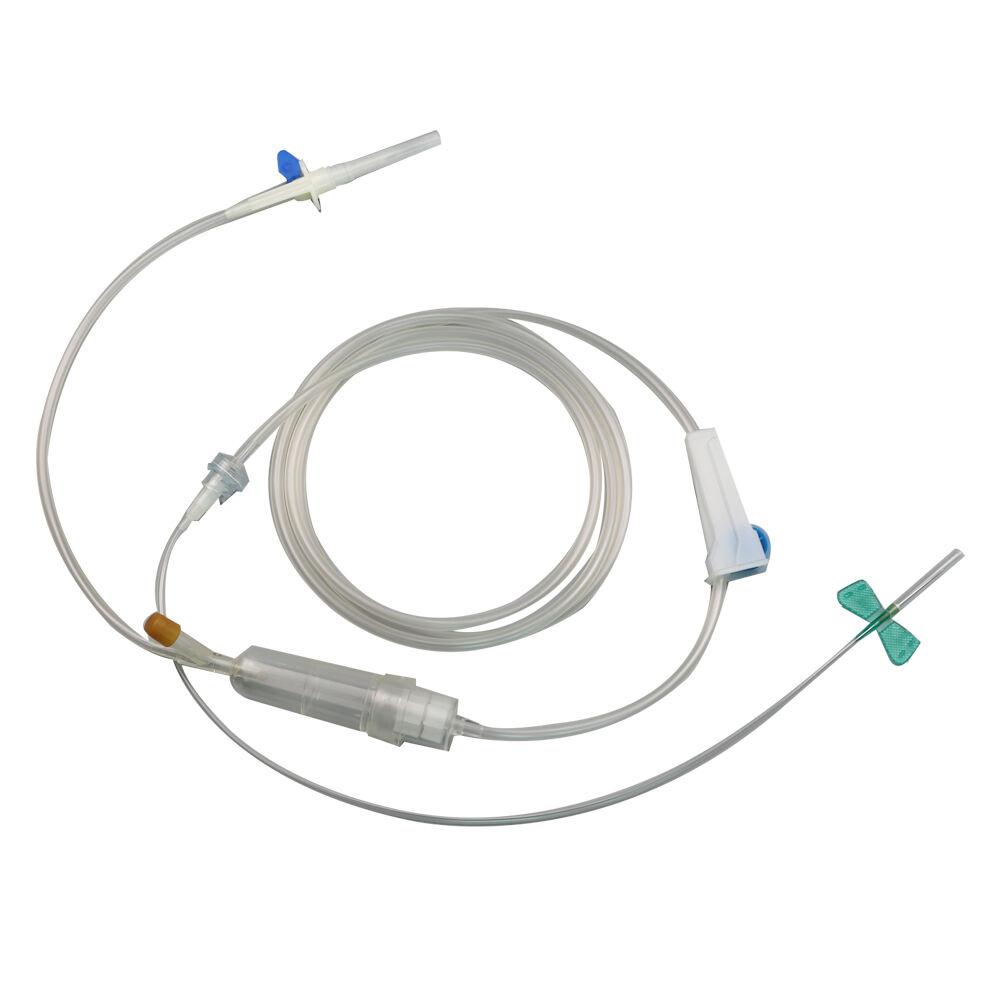

A disposable needle syringe manufacturer specializes in producing high-quality, single-use medical devices essential for healthcare settings worldwide. These facilities employ advanced automation systems and precision engineering to create sterile, reliable syringes that meet strict medical standards. The manufacturing process encompasses multiple stages, from raw material selection to final quality inspection, ensuring each product maintains consistent quality and safety standards. State-of-the-art clean rooms and automated assembly lines facilitate the production of various syringe sizes and needle gauges, catering to diverse medical requirements. The facilities utilize medical-grade materials, implementing rigorous quality control measures throughout the production cycle. Modern manufacturers incorporate innovative features such as safety mechanisms and ergonomic designs to prevent needlestick injuries and enhance user experience. They maintain compliance with international standards including ISO 13485 and FDA regulations, ensuring product safety and reliability. The manufacturing process includes precision molding of syringe barrels, needle attachment systems, and specialized packaging solutions that maintain product sterility until use.