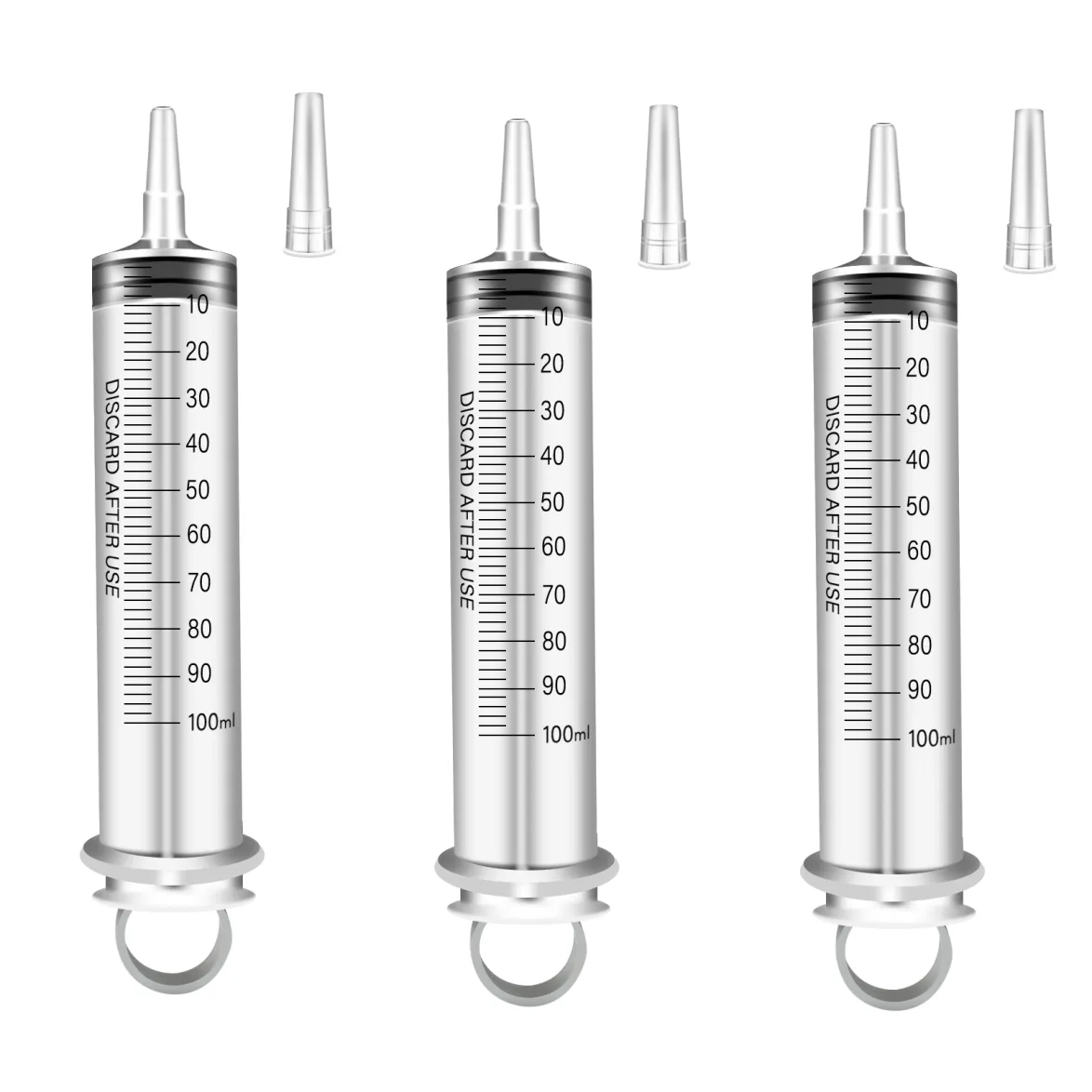

3ml 18g syringe manufacturer

As a leading 3ml 18g syringe manufacturer, our company specializes in producing high-precision medical devices that meet international quality standards. Our state-of-the-art manufacturing facility employs advanced automation technology to ensure consistent production of sterile, reliable syringes. The 3ml capacity combined with the 18-gauge needle size provides optimal flow rate and accuracy for various medical procedures. We utilize medical-grade materials that undergo rigorous quality control processes, ensuring each syringe meets strict regulatory requirements. Our manufacturing process incorporates innovative features such as precise graduation marks, smooth plunger action, and secure needle attachment mechanisms. The facility maintains ISO 13485 certification and follows GMP guidelines, demonstrating our commitment to quality and safety. Our syringes feature clear barrel markings, ergonomic finger grips, and specialized lubricants to ensure smooth operation. The manufacturing process includes multiple inspection points and automated quality checks to maintain consistent product quality. These syringes are designed for both manual and automated filling systems, making them versatile for various medical applications.