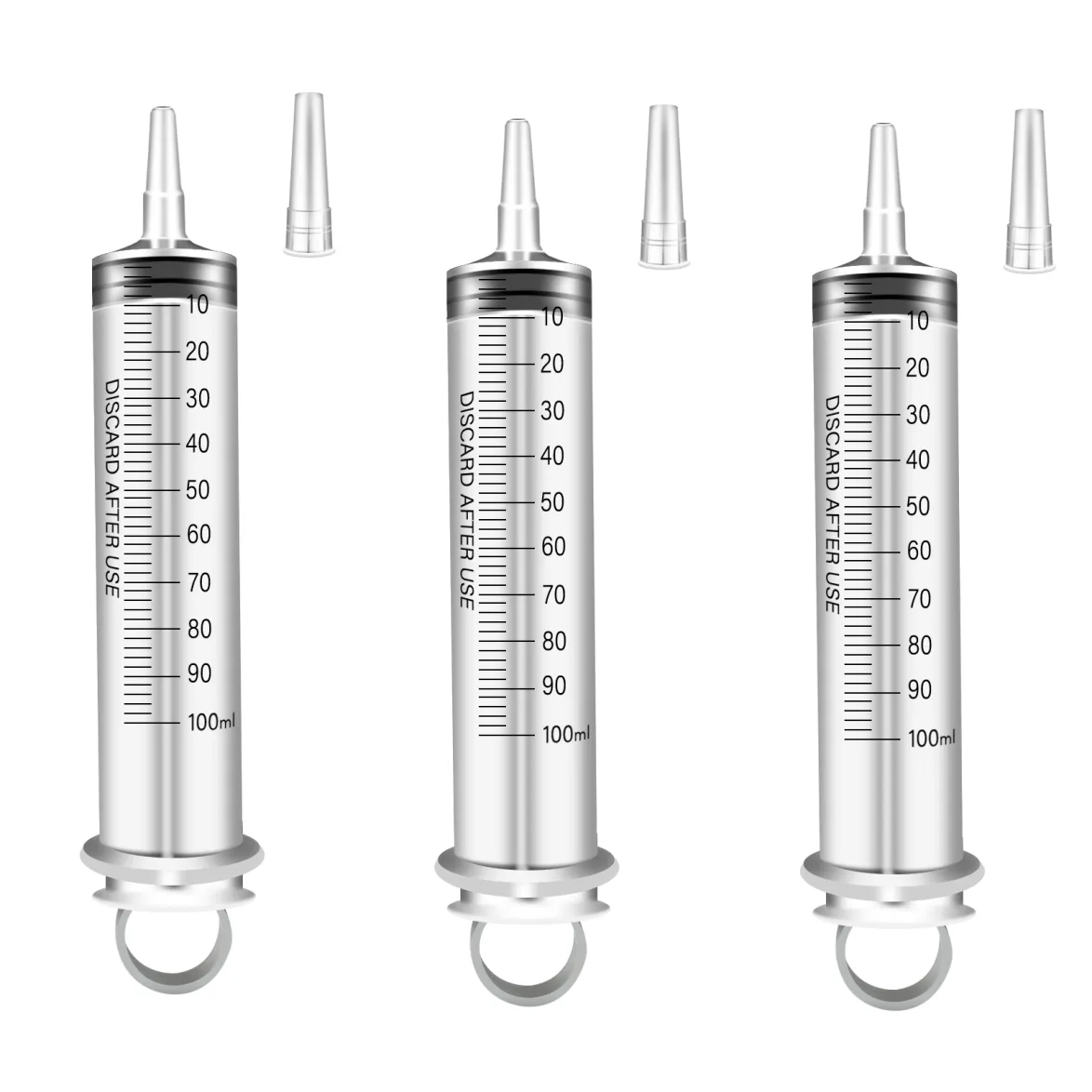

2 ml disposable syringe manufacturer

A 2 ml disposable syringe manufacturer specializes in producing precision medical devices essential for healthcare settings worldwide. These facilities employ state-of-the-art automation and quality control systems to ensure the production of sterile, accurate, and reliable syringes. The manufacturing process involves advanced injection molding technology, utilizing medical-grade polypropylene and other materials that meet strict regulatory standards including ISO 13485 and FDA requirements. The production line incorporates multiple quality checkpoints, from raw material testing to final product inspection, ensuring each syringe meets exact specifications for capacity, needle attachment strength, and smooth plunger action. Modern manufacturers implement clean room technology with controlled environments to maintain sterility throughout the production process. The facility's capabilities typically include high-speed automated assembly lines that can produce millions of units per month while maintaining consistent quality. These manufacturers also focus on sustainable practices, utilizing energy-efficient equipment and implementing waste reduction protocols. The syringes produced feature precise graduation marks, secure luer lock or luer slip connections, and smooth barrel surfaces for accurate medication delivery. Each unit undergoes rigorous testing for leak prevention, material integrity, and proper sterilization before packaging and distribution to healthcare facilities, pharmacies, and medical suppliers worldwide.